RECENT PROGRESS WITH

THE UNSW VANADIUM BATTERY

BY

MARIA SKYLLAS-KAZACOS

SCHOOL OF CHEMICAL ENGINEERING AND INDUSTRIAL CHEMISTRY

UNIVERSITY OF NEW SOUTH WALES, SYDNEY, 2052

INTRODUCTION

With increasing public awareness of issues such as global warming and declining

urban air quality, community pressure on governments and industry to clean up

the environment will see the inevitable shift away from the traditional fossil

fuels to renewable energy. Unfortunately, however for any new technology to gain

acceptance it must not only compete technically and environmentally, but also

economically with existing systems.

Recent research and development in the areas of wind and solar energy has led to

dramatic cost reductions which will allow these technologies to compete with

traditional electricity generation in the not too distant future. Already in

Australia, electricity generators are paying a premium price for so called

"green" energy, giving consumers the opportunity to support the

gradual introduction of renewable energy into the existing electricity grid

system. While a modest level of solar energy could be accommodated in the

electricity grid, however, the mismatch between the peak energy demand and solar

energy supply in different regions at various times of the year, means that an

efficient energy storage system would be required to capture and store high

levels of solar energy for domestic and industrial use.

The most efficient method for storing electrical energy is with electrochemical

cells or batteries. Although a number of secondary batteries have been under

development for many years, only the lead-acid and nickel-cadmium batteries have

to date achieved widespread commercial application. More recently the lithium

and nickel metal hydride batteries have emerged as excellent high energy density

alternatives, however, their current high cost has to date limited their use to

relatively small-scale portable equipment applications.

For a battery system to be economically viable for large-scale energy storage,

it must compete favourably with pumped water storage. Of all the new battery

technologies currently under development around the world, the redox flow cell

appears to offer the greatest promise as a low-cost, high efficiency system for

large-scale energy storage.

The vanadium redox battery being developed since 1984 in the School of Chemical

Engineering and Industrial Chemistry at the University of New South Wales

possesses many features which make it ideal for a large number of applications,

including solar energy storage, emergency back-up and load-levelling. The UNSW

vanadium redox battery, which falls into the general class of redox flow

batteries, employs solutions to store energy (1-5).

The use of solutions to store the energy overcomes many of the life limiting

problems associated with conventional batteries. Redox batteries can thus be

fully discharged without harm, they can be stored indefinitely at any

state-of-charge with only negligible self-discharge or irreversible capacity

loss, and there are no problems associated with shedding of active material, nor

short circuiting of the electrodes due to metal penetration of the separator.

FEATURES OF THE UNSW VANADIUM REDOX FLOW BATTERY

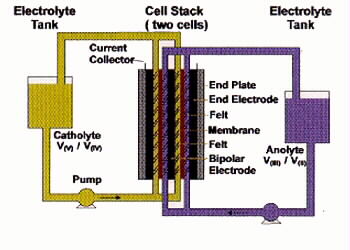

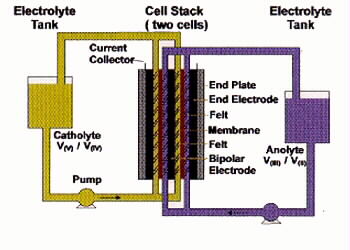

As illustrated in Figure 1, the Vanadium Redox Flow Battery employs the V(III)/V(II)

and V(V)/V(IV) redox couples in sulphuric acid as the negative and positive

half-cell electrolytes respectively.

Figure 1: Schematic of UNSW Vanadium Redox Flow Battery

The vanadium battery thus uses tanks to store two electrolyte "fuels"

which are pumped through a battery stack (power module) where the chemical

energy stored in the solutions is converted to electrical energy. The system is

analogous to an engine and fuel tank and provides great design flexibility by

separating the power source (battery stack) from the energy source (electrolyte

tanks).

In the vanadium redox cell, the following half-cell reactions are involved:

At the negative electrode:

V3+ + e- =====> V2+ E° = -0.26 V

At the positive electrode:

VO2+ + 2H+ + e- ======> VO2+

+ H2O E° = 1.00V

This gives a standard cell potential E° (cell) = 1.26 Volts at concentrations

of 1 mole per litre and at 25°C. Under actual cell conditions, an open-circuit

cell voltage of 1.4 Volts is observed at 50% state-of-charge, while a fully

charged cell produces over 1.6 Volts at open-circuit. The electrolyte for the

vanadium battery is 2 M vanadium sulphate in 2.5 M H2SO4,

the vanadium sulphate (initially 1 M V (III) + 1 M V (IV)) being prepared by

chemical reduction or electrolytic dissolution of V2O5

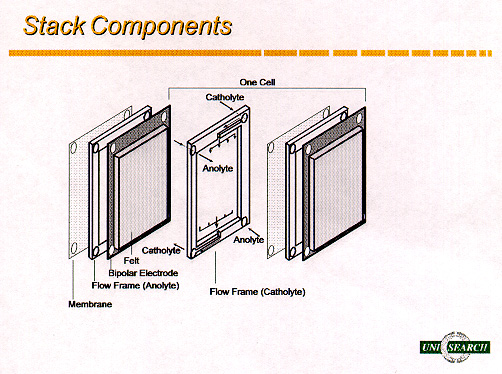

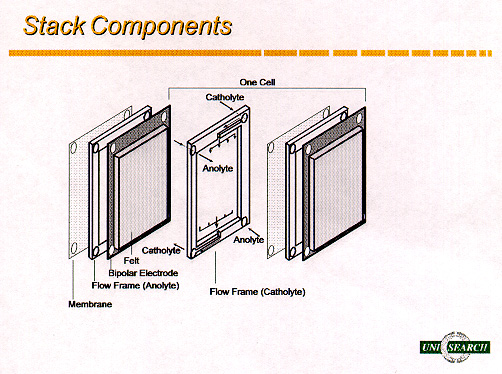

powder. The basic components of the redox cell are illustrated in Figure 2.

Figure 2: Components of the Redox Cell

The actual voltage needed to charge the battery and the voltage produced during

discharge when a load is connected, depend on the magnitude of the energy losses

associated with the internal resistance of the cell (R), the overvoltage losses

due to the kinetics of the system (activation overvoltage, na) and

the mass transport limitations (concentration overvoltage, nc):

Ecell = Ecathode - Eanode - iR - na

- nc

To maximise the cell voltage efficiency, therefore it is essential to minimise

the voltage losses during charging and discharging. The ohmic losses (iR) can be

minimised by selecting low resistivity membranes, electrode materials and other

cell components. The concentration overvoltage can be reduced with suitable cell

design to ensure good mass transport in the cell (i.e. high flow rate, uniform

electrolyte distribution).

The activation overvoltage depends on both the nature of the redox couple

reactions and the activity of the electrode material. The electrode material

used must also possess good stability during charging, good electrocatalytic

properties for the vanadium reactions and poor kinetics for hydrogen and oxygen

evolution so as to minimise gassing during charge. The relatively fast kinetics

of the vanadium redox couples allow high coulombic and voltage efficiencies to

be achieved without the use of expensive catalysts. The porous graphite felt

which is employed as the flow-through electrode, allows excellent mass-transfer

and permits greater surface area for the oxidation and reduction reactions.

The separator or membrane must be permeable to the charge balancing ions of the

supporting electrolyte, but prevent diffusion of the active species in solution

which would result in self-discharge of the battery. The ideal membrane should

thus exhibit low permeation rates of the active species to minimise

self-discharge and allow high coulombic efficiencies to be achieved. It should

also have a low resistivity to minimise losses in voltage efficiency, and it

should exhibit chemical stability for long cycle life.

The voltage of the battery is determined by the number of cells that are

connected electrically in series (using bipolar electrodes) in the cell stack.

The current on the other hand, is determined by the electrode area. The size of

the cell stack thus determines the output power of the system. The energy

storage capacity, however, is a function of the electrolyte volume.

For a vanadium concentration of 2 M, the energy density of the vanadium battery

is approximately 25 Wh/kg, this being acceptable for stationary applications.

Typically 30 litres of electrolyte (total volume) is needed per kWh of energy

storage. At higher vanadium concentrations, the required electrolyte volume can

be reduced, making the system more attractive for electric vehicles.

PROTOTYPE DEVELOPMENT AND FIELD TESTING

After selecting the most suitable electrode and membrane materials for

small-scale cell test results, their performance in larger prototype batteries

has been evaluated under continuous long-term cycling over a wide range of

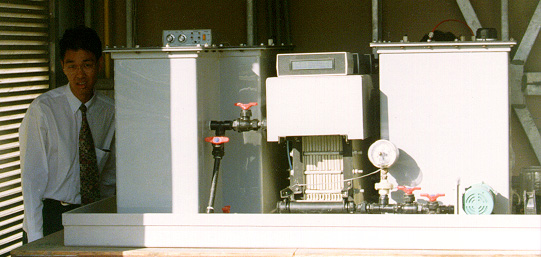

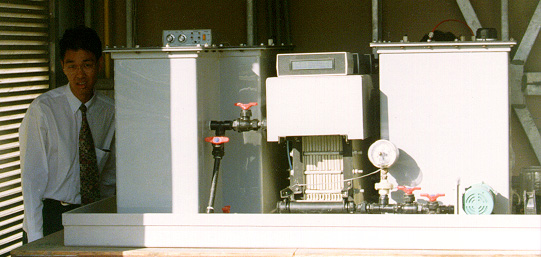

operating conditions..The vanadium battery is now at a relatively advanced stage

of development with several 1-3 kW prototype batteries already constructed and

tested at UNSW. Overall energy efficiencies as high as 90% have been achieved

with early prototypes, not including pumping energy losses (3). These have been

estimated at 2-3%, so that even at 87-88% overall energy efficiency, the

vanadium battery is proving to be one of the most efficient energy storage

systems currently under development.

Since 1993 a number of field trials of the vanadium battery have been undertaken

both by UNSW and the University's licensees in Thailand and Japan. Details of

these trials are presented below:

(a) Vanadium Battery Solar House Trail in Thailand

In collaboration with UNSW Centre for Photovoltaic Device and Systems and

licensee Thai Gypsum Products Ltd, a vanadium battery storage system was

installed by the UNSW Vanadium Battery Group in a demonstration Solar House in

Thailand (6).

The solar energy system included 2.2 kW of installed solar cells and a 1 kW/12

kWh vanadium battery. The demonstration Solar House and installed vanadium

battery are shown in Figures 3 and 4 respectively. The original battery had 12

cells giving a system voltage of 16.8 volts and used 200 litres of each ½ -cell

electrolyte in the two reservoirs.

A 48 volt, 36 cell stack was later constructed in the laboratory and tested with

a 4 kW inverter and specially designed battery controller, prior to installation

in the demonstration Solar House in Thailand. The 48 volt battery replaced the

original 12-cell stack for long-term field trials.

Figure 3: Photograph of demonstration Solar House in Thailand

Figure 4: 1 kW/12 kWh Prototype Vanadium Battery Installed in Thailand Solar

House

The microprocessor controller built by the UNSW Centre for Photovoltaic Systems

and Devices, was designed to optimise the efficiency of the battery for this

application. One of the principal functions is to turn the pumps off during

periods of low charge or discharge rates so as to mimimise the pumping energy

losses in the system. Even with the pumps off approximately 1 kWh of energy is

stored in the battery stack itself. When the energy level of the stack

electrolytes reaches a preset threshold (as indicated by the stack voltage), the

pumps are turned on for 3-4 minutes so as to flush the stack with fresh

electrolytes before being turned off again. When the charging or discharging

current exceeds 20 Amps, however, the pumps operate continuously.

Another important feature of the vanadium battery is the fact that there is

negligible hydrogen evolution during charging and so there is no need for forced

ventilation. The battery room (Figure 4) is designed, however, to provide

natural ventilation (it is important to avoid high ambient temperatures) and

easy access for installation and maintenance.

One of the maintenance procedures which is used to rebalance the electrolytes

and restore the battery's full capacity, involves the periodic remixing of the

two solutions through a bypass line which connects the two tanks. This

rebalances the vanadium concentrations in the two half-cells, producing a

solution containing 50% V(III) and 50% V(IV) ions. On recharging the 2

solutions, the system's full capacity can be restored.

Depending on the system operation and type of membrane used, the remixing could

be required every 3-4 months.

Thai Gypsum is currently developing appropriate production methods for the

manufacture of electrodes and other battery components and is also evaluating

the feasibility of using vanadium batteries as peak shaving and emergency back

up systems in office buildings in Thailand.

(b) 200 kW/800 kWh Loading-Levelling Vanadium Demonstration Battery in Japan

In 1993, a consortium comprising Mitsubishi Chemicals and Kashima-Kita Power

Corporation of Japan licensed the UNSW vanadium battery technology for

stationary uses and has since spent several million dollars each year to scale

up the technology for large-scale load-levelling and solar energy storage

applications.

Kashima-Kita Electric Power Corporation employs vanadium rich Venezualan pitch

as the fuel for electricity generation, thus producing a high vanadium content

fly-ash as a waste product. An efficient chemical process was developed to

extract the vanadium from the fly-ash which is then used to produce a low-cost

vanadium electrolyte for the vanadium redox flow battery. A 3m3/day electrolyte

production plant was commissioned in early 1996.

In 1997, a 200 kW/800 kWh grid-connected vanadium battery was commissioned at

the Kashima-Kita Electric Power station in Japan where it is currently

undergoing long-term testing as a load-levelling system. By the beginning of

1998, it had already undergone 150 charge-discharge cycles and was continuing to

show high energy efficiencies of close to 80% at current densities of 80-100 mA/cm2.

The specifications of the 200 kW/800 kWh battery are as follows:

Number of stack modules = 8 x 25 kW stacks

Stack configuration = 3 substacks per stack (21 cells per substack)

Electrode area = 4000 cm2

Electrolyte volume = 23 m3

Electrolyte vanadium concentration = 1.8 mol/l

System voltage = 500 V

Charge and discharge current = 400 Amps

The 200 kW vanadium battery stack modules are shown in Figure 5.

Figure 5: 200 kW Vanadium Battery Modules at Kashima-Kita Power Plant in Japan

As in the case of solar energy storage, the important features of the vanadium

battery for this application are:

· Low cost for large storage capacities. Cost per kWh decreases as energy

storage capacity increases, typical projected battery costs for 8 or more hours

of storage being as low as US$150 per kWh.

· Existing systems can be readily upgraded and additional storage capacity can

be easily installed by changing the tanks and volumes of electrolyte.

· High energy efficiency.

· Capacity and state-of-charge of the system can be easily monitored by

employing an open-circuit cell.

· Easy maintenance.

· Flexibility.

(a) UNSW Emergency Back-Up Battery for Submarine Applications

A VRB emergency back-up battery was recently designed and built at UNSW to meet

the desired operating conditions specified by the Department of Defence (7). Its

intent was to allow a comparison with the current nickel/cadmium system employed

as a back-up battery in submarines. The primary requirements for the VRB Defence

system were that it should be charged between 5% and 95% of its rated capacity

while remaining in the voltage range of 22 V to 28 V under loads of 0 to 160 A.

The capacity of the current nickel/cadmium system was 160 Ahr, therefore, the

VRB Defence battery was designed to meet and preferably exceed this capacity,

even at high constant loads.

Unlike other battery systems the charge and discharge voltage of the vanadium

battery stack can be chosen by introducing tapped cells. This provides the

opportunity to change the operating conditions so as to protect sensitive

equipment from large voltage fluctuations and allow operation within a narrow

voltage window for charging and discharging.

The vanadium redox battery emergency back-up system shown in Figure 6, comprises

of two battery stacks electrically connected in parallel, each containing 19

cells with a tapping cell placed at cell No. 17 in each stack. The battery is

thus charged across 17 cells and discharged across 19 cells, thus allowing an

overall voltage window of 22 to 28 volts to be maintained during charge and

discharge.

Figure 6: Vanadium Redox Battery Defence Emergency Back-Up System.

The battery was charged and discharged at a range of currents ranging from 40 to

120 Amps and high overall energy efficiencies of 77 to 81% were obtained, even

with the high charging currents.

The theoretical maximum capacity of the system based on 19 cells and 83 litres

of 1.8 M vanadium solution per half-cell series, is calculated as 210.8 Ahr.

Discharging the battery across 19 cells from a fully charged state to a lower

voltage limit of 22 V, produced 183 to 162 Amphours over the discharge current

range of 60 to 120 Amps.

This represents an utilisation of between 77 and 87% of the theoretical

capacity, which again is an excellent result.

(b) UNSW Vanadium Battery Powered Electric Golf Cart

One of the unique features of the vanadium battery which makes it highly

attractive for mobile application is its ability to be both electrically

recharged and mechanically recharged by exchanging electrolytes.

Although there are a number of high profile battery technologies under

development, these currently suffer from an anticipated high whole of life cost

together with various functional limitations including slowness in recharging

and cooling.

In contrast to these essentially complex batteries, the vanadium redox flow

battery is an inherently simple battery with potential for low manufacturing

cost and demonstrated indifference to deep cycling and very high charge and

discharge rates.

In order to demonstrate the vanadium battery in a mobile application, therefore,

a 36 volt vanadium battery prototype was installed in a commercially available

electric golf cart at UNSW in 1994 where it was subjected to over 2 ½ years of

off-road testing (8). The photograph in Figure 7 shows the vanadium battery

powered golf cart with the 5 kW battery stack mounted on the back and

electrolyte tanks under the seat. This 5 kW stack is considerably oversized for

this application and with suitable re-engineering a compact stack of one-quarter

of the present size should be achievable.

Figure 7: UNSW Vanadium Battery Powered Electric Golf Cart

To achieve a compact stack design, thinner flow-frame dimensions (3 mm compared

with original 5 mm) were employed in a second prototype stack which was

installed in the golf cart in early 1997.

Extensive off-road trials of this battery showed excellent performance over a

range of terrains. With 40 litres of 1.85 M vanadium electrolyte per half-cell

tank, a driving range of 17 km was obtained. The total driving range expected

for 3 molar vanadium solutions and full tanks containing 60 litres each side,

therefore, is around 40 km.

A new improved 3 M vanadium solution has been undergoing bench-testing since

late 1997 and is currently being evaluated in the golf-cart battery. Preliminary

results look very promising and if long-term testing prove to be successful, a

practical 3 molar vanadium electrolyte with energy density of over 35 Wh/kg will

be available for commercial application. Further research into air regeneration

of the positive electrolyte, should double this to over 70 kW/kg (9).

While the present energy density is relatively low compared with new high energy

density systems like the lithium, nickel-metal hydride and sodium nickel

chloride batteries, a practical driving range of around 120 km would still be

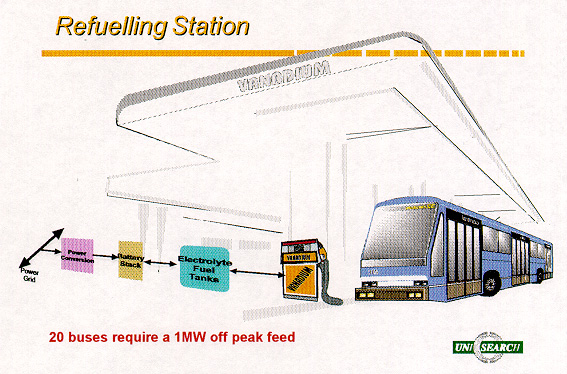

expected in an electric vehicle applications. In particular, the use of vanadium

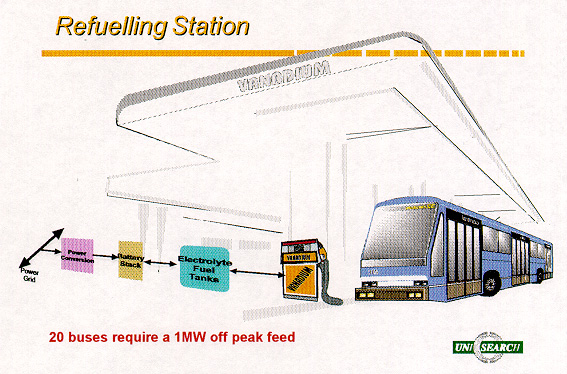

batteries in electric buses would allow 24 hour a day use of the buses if

electrolyte refueling is employed every 4-5 hours during driver rest breaks as

illustrated in Figure 8.

Figure 8: Vanadium Battery Refueling Station Concept for Electric Buses.

CONCLUSIONS

Several demonstration projects at both UNSW and overseas have shown the

technical viability of the vanadium battery for a wide range of stationary and

mobile applications.

The vanadium battery is at an early stage of its productionisation and

manufacturing life cycle and it is expected that manufacturing costs will be

reduced rapidly with improved materials, more advanced mechanical design,

process improvements and volume manufacturing economies.

Cost estimates by the UNSW group and independent consulting groups (10, 11),

place mass production costs at between $100 and $300 per kW for the stack and

$30 to $50 per kWh for the electrolyte.

In addition to the low projected manufacturing costs, other attractive features

of the vanadium battery include:

· Ability to accept rapid charging/discharging rates.

· Potential for long life and consequent low whole of life costs.

· Five minute recharging by electrolyte replacement.

· Self-cooling (of special importance in large dense battery stacks).

· Positive environment impact.

When combined with newly increased energy (12) and power density the vanadium

battery is one of only a few battery technologies which hold realistic promise

for large-scale energy storage in the near term and for successfully powering

production electric vehicles beyond 2000.

In September 1998 all patents, technology, know how and licenses associated with

the vanadium battery were bought by an Australian company, PinnacleVRB, who plan

to commercialise the technology for stationary and mobile applications.

REFERENCES

(1) M. Skyllas-Kazacos and R G Robins, "The All Vanadium Redox

Battery", US Patent No. 849, 094 (1986).

(2) M Kazacos and M Skyllas-Kazacos, "Performance Characteristics of Carbon

Plastic Electrodes in Vanadium Redox Cell", J Electrochem. Soc. 136, 2759

(1989).

(3) M Skyllas-Kazacos, D Kasherman, D R Hong and M Kazacos,

"Characteristics and Performance of 1 kW UNSW Vanadium Redox Battery",

J Power Sources, 35, 399-404 (1991).

(4) "Status of the UNSW Vanadium Redox Battery Development", M

Skyllas-Kazacos, in Proceedings 9th Australasian Electrochemical Conference,

Wollongong, February 1994, pp 033-1 to 033-4.

(5) "Conductive Carbon-Polypropylene Composite Electrodes for Vanadium

Redox Flow Battery", V Haddadi-Asl, M Kazacos and M Skyllas-Kazacos, J Appl

Electrochem., 25, 29-33 (1995).

(6) R Largent, M Skyllas-Kazacos and J Chieng, "Improved PV System

Performance using Vanadium Batteries", Proceedings IEEE 23rd Photovoltaic

Specialists Conference, Louisville, Kentucky, May 1993.

(7) "Vanadium Back up Battery for Submarine Application", C Menictas,

D R Hong, M Kazacos and M Skyllas-Kazacos, Final Report, Australian Defence

Dept., Oct., 1995, pp120.

(8) "Status of the Vanadium Redox Battery Development Program", C

Menictas, D R Hong, Z H Yan, J Wilson, M Kazacos and M Skyllas-Kazacos,

Proceedings Electrical Engineering Congress 1994, Sydney, NSW, November 1994.

(9) "Vanadium/Oxygen Redox Fuel Cell" by C Menictas and M

Skyllas-Kazacos, Final Report to NSW Office of Energy, State Energey Research

and Development Fund, April 1997.

(10) "Commissioned Study into the Prospects for Using Energy Storage in

Australia", Report to Dept of Primary Industries and Energy by McLennan

Magasanik Associates Pty Ltd, January 1990.

(11) "Viability Assessment of Vanadium Redox , Battery Manufacturing in

Australia", Report to Energy Research Development Corporation by Strategic

Industry Research Foundation, April 1995.

(12) "High Energy Density Vanadium Electrolyte Solutions for all-Vanadium

Redox Battery" M Skyllas-Kazacos and M Kazacos, International Patent

Application No. PCT/AU96/00268, May 1996.