October 28, 2004

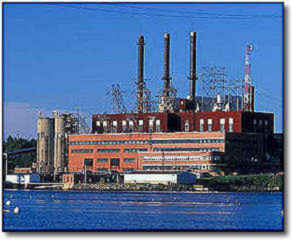

The Schiller power plant in Portsmouth, NH, where 50 MW of coal-fired power generation will soon be replaced by a biomass boiler.

Photo: PSNH

|

October 28, 2004 The Schiller power plant in Portsmouth, NH, where 50 MW of coal-fired power generation will soon be replaced by a biomass boiler. Photo: PSNH |

Portsmouth, New Hampshire [RenewableEnergyAccess.com] After its official groundbreaking, the Northern Wood Power Project, New Hampshire's first non-hydro, commercial-scale renewable energy project, is now underway at the Schiller Station in Portsmouth.

The US$75 million project, developed by Public Service of New Hampshire (PSNH),

will replace a 50 MW coal-fired boiler with a new boiler of equal size that will

burn wood chips and other clean wood products. In addition to creating a market

for woodchips from the state's many logging operations, the facility will become

a major regional contributor of renewable energy.

"New Hampshire will benefit from a dramatic reduction in air emissions, an

estimated $20 million boost to the local economy, and a new market for 400,000

tons of wood chips annually to boost the state and region's forest

industry," said Gary Long, PSNH president and chief operating officer, at a

groundbreaking ceremony at the site of the project along the New Hampshire

seacoast.

Like its coal-fired predecessor before it, the wood-fired boiler will be capable

of producing 50 MW of energy, which is enough electricity to power about 50,000

homes. However, it will do so with a much lower rate of emissions. PSNH

estimates that the wood-fired boiler will result in a reduction of more than

380,000 tons of emissions annually, while offering a major boost of renewable

energy to the local electric grid.

While the term 'renewable energy' often evokes visions of high tech solar panels

or sleek wind turbines, co-fired biomass plants are an especially effective form

of renewable energy. Particularly in a rural state such as New Hampshire that

boasts an abundance biomass resources from logging and other wood-related

operations.

According to the U.S. Department of Energy's Biomass Program, when power

producers have access to very low cost biomass supplies the choice to use

biomass in the fuel mix enhances their competitiveness in the marketplace. This

is particularly true in the near term for power companies choosing to co-fire

biomass with coal to save fuel costs and earn emissions credits or credits for

environmentally-friendly electricity.

Power plants are generally only as clean as their feedstock -- the material

being burned. New Hampshire's experience with biomass plants has sometimes lead

to some friction.

According to New Hampshire's Concord Monitor newspaper, during three months in

1995, a facility based in Hopkinton called Bio Energy burned wood from

construction and waste debris that released unknown levels of lead into the air.

The state's Department of Environmental Services deemed the incident an

unintentional oversight and no penalties were levied.

The lead issue isn't over, however, as Bio Energy was recently granted

permission to burn painted wood and other wood from construction and demolition

debris. According to the Concord Monitor article, it could become the largest

industrial source of lead in the state, being allowed to emit up to 2.67 tons of

lead each year.

PSNH's Northern Wood Power Project is likely to steer clear of any such concerns

as no demolition material will be burned in the new boiler, according to company

spokesman, Martin Murray.

"We did not seek, nor were we granted, an air permit which would allow such

burning," Murray said. "We expect all of our wood to come from NH, New

England logging operations, as well as some clean scrap wood - from

construction, for example - or clean pallets."

The nearby states of Massachusetts and Connecticut seem to have no doubt the

facility will be a clean, renewable energy project, as they have offered

important backing.

The 50 MW boiler meets the strict efficiency and environmental standards for the

renewable energy programs in Massachusetts and Connecticut. The Northern Wood

Power Project has been certified by both states as a new, renewable energy

source, enabling it to produce and sell "Renewable Energy

Certificates" (RECs) to suppliers seeking to satisfy renewable energy

requirements. The Massachusetts Technology Collaborative has made long term REC

commitments, thereby adding an important revenue stream for the new facility.

There's even a chance federal government policies could help the project. The

recently approved federal renewable energy Production Tax Credit (PTC) is not

expected to directly benefit the project since the legislation, as it is

currently written, applies only to projects that come on-line by the end of

January 1, 2006. The PTC now does recognize such a project as an open-loop

biomass generator of renewable energy, opening up the chance for the facility to

qualify if the legislation's 'on-line' date is modified.

"In any event, PSNH used conservative budget numbers in justifying the

project from a business and customer perspective," Murray said. "We

did not figure any tax credit dollars into the plan. If, in the future, we do

receive such a credit it will mean a lower overall cost for the project and a

quicker payback for our customers."

As of now PSNH does not have any active plans for further renewable energy

projects, but Murray said that in the new deregulated atmosphere the utility

could further modify existing generation plans. Much as they are doing at the

Schiller plant with the Northern Wood Power Project.

Other independent companies are also likely to step up to the plate buy

constructing their own generation facilities.

"Our PSNH role will be to work with such companies so that they can tie-in

to our transmission system," Murray said.

Construction crews are expected to begin work at the Schiller power plant by the

end of the month. It is hoped that the Northern Wood Power Project will be

online and generating renewable energy by the summer of 2006.

Copyright © 1999 - 2004 - RenewableEnergyAccess.com

Please visit www.RenewableEnergyAccess.com for great coverage on energy today!!