QuantumSphere to Present New Electrode Design for Hydrogen Electrolysis;

Nearly a 7x Increase in H2 Production

15 March 2007

|

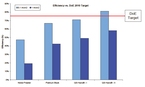

| Earlier results of QSI electrode development. Click to enlarge. |

QuantumSphere, Inc. (QSI) will present the results of its recent research into increasing efficiencies of electrodes made from compressed nano catalysts for hydrogen electrolysis, as well as a new concept in electrode design it calls Stingray, at the upcoming National Hydrogen Association meeting in San Antonio.

The Stingray electrode and system design allows for nearly a sevenfold increase in clean hydrogen production, while maintaining efficiencies in excess of 85%, according to QuantumSphere.

The presentation will also cover the effect of the use of QSI-Nano catalysts mixed with larger electrode components to give hydrogen generation efficiencies “well above the US Department of Energy’s 2010 targets [75%], and well ahead of the literature to date.”

QSI developed a unique electrode structure for alkaline water electrolysis by capitalizing on the enhanced surface area and catalytic reactivity of its nanometal catalysts. The QSI technology also eliminates the need for platinum precious metal catalysts, further reducing electrolyzer cost.

The high surface area metallic nanoparticles have an expanded metal surface facing away from the electrolyte for strength and current collection. The electrodes have tortuous pathways within them to expose orders of magnitude larger surface area to reacting water and to also allow the escape of the gaseous products.

Earlier this year, QSI also announced that it had achieved a 45% enhancement in power for a direct methanol fuel cell (DMFC) through the use of QSI-Nano Cobalt into the membrane electrode assembly (MEA), along with an almost 50% reduction in cost.

Resources:

|

www.pureenergysystems.com |