Purdue Process Generates Hydrogen from Aluminum Alloy

Water added to aluminum mixed with Gallium can produce hydrogen

on demand. As a catalyst, the Gallium is not consumed. The oxidized

aluminum can be recycled. The process is close to being cost competitive

with petrol.

adapted from press release

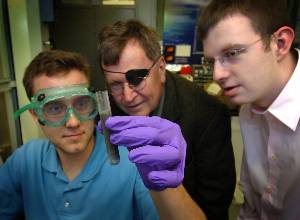

Purdue researchers demonstrate their

method for producing hydrogen by adding water to an alloy of

aluminum and gallium. The hydrogen could then be used to run an

internal combustion engine. The reaction was discovered by Jerry

Woodall, center, a distinguished professor of electrical and

computer engineering. Charles Allen, holding test tube, and Jeffrey

Ziebarth, both doctoral students in the School of Electrical and

Computer Engineering, are working with Woodall to perfect the

process.

(Purdue News Service photo/David Umberger) |

WEST LAFAYETTE, INDIANA, USA -- A Purdue University engineer has

developed a method that uses an aluminum alloy to extract hydrogen from

water for running fuel cells or internal combustion engines. The

technique could be used to replace gasoline, though it is not quite

cost-competitive yet.

The method makes it unnecessary to store or transport hydrogen - two

major challenges in creating a hydrogen economy, said Jerry Woodall, a

distinguished professor of electrical and computer engineering at Purdue

who invented the process.

"The hydrogen is generated on demand, so you only produce as much as you

need when you need it," said Woodall, who presented research findings

detailing how the system works during a recent energy symposium at

Purdue.

The technology could be used to drive small internal combustion

engines in various applications, including portable emergency

generators, lawn mowers and chain saws. The process could, in theory,

also be used to replace gasoline for cars and trucks, he said.

Hydrogen is generated spontaneously when water is added to pellets of

the alloy, which is made of aluminum and a metal called gallium. The

researchers have shown how hydrogen is produced when water is added to a

small tank containing the pellets. Hydrogen produced in such a system

could be fed directly to an engine, such as those on lawn mowers.

"When water is added to the pellets, the aluminum in the solid alloy

reacts because it has a strong attraction to the oxygen in the water,"

Woodall said.

This reaction splits the oxygen and hydrogen contained in water,

releasing hydrogen in the process.

The gallium is critical to the process because it hinders the formation

of a skin normally created on aluminum's surface after oxidation. This

skin usually prevents oxygen from reacting with aluminum, acting as a

barrier. Preventing the skin's formation allows the reaction to continue

until all of the aluminum is used.

The waste products are gallium and aluminum oxide, also called alumina.

Combusting hydrogen in an engine produces only water as waste.

As a catalyst, the gallium is not consumed, and hence does not need to

be replenished. The alumina can be recharged in a separate process,

preferably using renewable energy.

The Purdue Research Foundation holds title to the primary patent, which

has been filed with the U.S. Patent and Trademark Office and is pending.

An Indiana startup company, AlGalCo LLC., has received a license for the

exclusive right to commercialize the process.

Woodall discovered that liquid alloys of aluminum and gallium

spontaneously produce hydrogen if mixed with water while he was working

as a researcher in the semiconductor industry in 1967. The research,

which focused on developing new semiconductors for computers and

electronics, led to advances in optical-fiber communications and

light-emitting diodes, making them practical for everything from DVD

players to automotive dashboard displays. That work also led to

development of advanced transistors for cell phones and components in

solar cells powering space modules like those used on the Mars rover,

earning Woodall the 2001 National Medal of Technology from President

George W. Bush.

"I was cleaning a crucible containing liquid alloys of gallium and

aluminum," Woodall said. "When I added water to this alloy - talk about

a discovery - there was a violent poof. I went to my office and worked

out the reaction in a couple of hours to figure out what had happened.

When aluminum atoms in the liquid alloy come into contact with water,

they react, splitting the water and producing hydrogen and aluminum

oxide.

"Gallium is critical because it melts at low temperature and readily

dissolves aluminum, and it renders the aluminum in the solid pellets

reactive with water. This was a totally surprising discovery, since it

is well known that pure solid aluminum does not readily react with

water."

"No toxic fumes are produced," Woodall said. "It's important to note

that the gallium doesn't react, so it doesn't get used up and can be

recycled over and over again. The reason this is so important is because

gallium is currently a lot more expensive than aluminum. Hopefully, if

this process is widely adopted, the gallium industry will respond by

producing large quantities of the low-grade gallium required for our

process. Currently, nearly all gallium is of high purity and used almost

exclusively by the semiconductor industry."

Woodall said that because the technology makes it possible to use

hydrogen instead of gasoline to run internal combustion engines it could

be used for cars and trucks. In order for the technology to be

economically competitive with gasoline, however, the cost of recycling

aluminum oxide must be reduced, he said.

"Right now it costs more than $1 a pound to buy aluminum, and, at that

price, you can't deliver a product at the equivalent of $3 per gallon of

gasoline," Woodall said.

However, the cost of aluminum could be reduced by recycling it from the

alumina using a process called fused salt electrolysis. The aluminum

could be produced at competitive prices if the recycling process were

carried out with electricity generated by a nuclear power plant or

windmills. Because the electricity would not need to be distributed on

the power grid, it would be less costly than power produced by plants

connected to the grid, and the generators could be located in remote

locations, which would be particularly important for a nuclear reactor

to ease political and social concerns, Woodall said.

"The cost of making on-site electricity is much lower if you don't have

to distribute it," Woodall said.

The approach could enable the United States to replace gasoline for

transportation purposes, reducing pollution and the nation's dependence

on foreign oil. If hydrogen fuel cells are perfected for cars and trucks

in the future, the same hydrogen-producing method could be used to power

them, he said.

"We call this the aluminum-enabling hydrogen economy," Woodall said.

"It's a simple matter to convert ordinary internal combustion engines to

run on hydrogen. All you have to do is replace the gasoline fuel

injector with a hydrogen injector."

Even at the current cost of aluminum, however, the method would be

economically competitive with gasoline if the hydrogen were used to run

future fuel cells.

"Using pure hydrogen, fuel cell systems run at an overall efficiency of

75 percent, compared to 40 percent using hydrogen extracted from fossil

fuels and with 25 percent for internal combustion engines," Woodall

said. "Therefore, when and if fuel cells become economically viable, our

method would compete with gasoline at $3 per gallon even if aluminum

costs more than a dollar per pound."

The hydrogen-generating technology paired with advanced fuel cells also

represents a potential future method for replacing lead-acid batteries

in applications such as golf carts, electric wheel chairs and hybrid

cars, he said.

The technology underscores aluminum's value for energy production.

"Most people don't realize how energy intensive aluminum is," Woodall

said. "For every pound of aluminum you get more than two kilowatt hours

of energy in the form of hydrogen combustion and more than two kilowatt

hours of heat from the reaction of aluminum with water. A midsize car

with a full tank of aluminum-gallium pellets, which amounts to about 350

pounds of aluminum, could take a 350-mile trip and it would cost $60,

assuming the alumina is converted back to aluminum on-site at a nuclear

power plant.

"How does this compare with conventional technology? Well, if I put

gasoline in a tank, I get six kilowatt hours per pound, or about two and

a half times the energy than I get for a pound of aluminum. So I need

about two and a half times the weight of aluminum to get the same energy

output, but I eliminate gasoline entirely, and I am using a resource

that is cheap and abundant in the United States. If only the energy of

the generated hydrogen is used, then the aluminum-gallium alloy would

require about the same space as a tank of gasoline, so no extra room

would be needed, and the added weight would be the equivalent of an

extra passenger, albeit a pretty large extra passenger."

The concept could eliminate major hurdles related to developing a

hydrogen economy. Replacing gasoline with hydrogen for transportation

purposes would require the production of huge quantities of hydrogen,

and the hydrogen gas would then have to be transported to filling

stations. Transporting hydrogen is expensive because it is a "non-ideal

gas," meaning storage tanks contain less hydrogen than other gases.

"If I can economically make hydrogen on demand, however, I don't have to

store and transport it, which solves a significant problem," Woodall

said.

# # #

SOURCE:

|