By: Chris Webb

Two years ago Germany’s E.ON, the company that runs Powergen in the UK, began the process of creating Britain’s first large pilot-scale carbon capture test rig. The company began converting a 1 MW combustion test facility (CTF) at its Power Technology unit in Nottingham to fire coal in pure oxygen and exhaust gas. The ‘oxyfuel combustion’ project took its place beside other promising technologies vying for the main prize: carbon capture and storage (CCS) on a commercially viable scale.

By burning coal in this way, the team aimed to produce pure carbon dioxide (CO2), which could then be piped out of a power station and stored underground. If the project proved feasible, both practically and commercially, it could lead the way to a new generation of coal fired power stations in the UK, with dramatically reduced CO2 emissions. It could also help secure diversity in sources of fuels, thus prolonging the life of fossil-fired power plants at a time when ‘carbon’ is increasingly regarded as a dirty word.

The company is also looking at a possible carbon sequestration project at its Killingholme gas fired plant.

Carbon capture competition in the UK

E.ON also aims to take part in the UK government’s competition, detailed in the Energy White Paper earlier this year by the then trade and industry secretary, Alistair Darling, to build the first CCS plant. The contest is being avidly promoted by the Department for Business, Enterprise and Regulatory Reform (DBERR), which succeeds the Department of Trade and Industry.

E.ON’s Killingholme plant: potential carbon sequestration site |

CCS technologies allow fossil fuels to be used with minimum emissions. The idea of carbon sequestration is simple and powerful: segregate the CO2 from the fossil fuel combustion products, and then deposit it in a place where it will remain. The emission of CO2 from such a plant could be reduced to virtually zero if the clean coal plant was designed to sequester carbon. The CO2 could be disposed of, for example, in the emptying oil fields of the North Sea, which consequently can extend the lives of oil fields through pressure being applied on old and difficult to extract reserves, thereby prolonging production.

Much is expected of CCS technology, but the UK, once in the forefront, may already have lost the race to be first with a demonstration project. Energy giant BP’s scrapping of plans for a 375 MW carbon capture and storage (CCS) power project in Scotland dealt a bitter blow to British hopes of being the first to prove the climate change-beating technology. Had the scheme at Peterhead gone ahead, it would have locked up an estimated 1.8 million tonnes of CO2 a year from a gas-fired power station and helped win an extra 40 million barrels of otherwise unrecoverable oil from the nearby, and now probably doomed, Miller North Sea oil field.

Frustrated by delayed government support, BP axed the scheme it had kept alive in the hope of showing a world lead for fuel decarbonization and undersea gas storage technology. Now that accolade could go to Australia or the USA, say observers.

American sequestration efforts

In the USA, efforts are continuing apace, with sequestering options focusing on geologic, terrestrial ecosystem, or oceanic approaches. Control of fugitive methane emissions is also being addressed with similar vigour. Carbon sequestration work in the United States is aimed at implementing President Bush’s global climate change initiative, as well as several national energy policy goals targeting the development of new technologies.

It also supports the goals of the Framework Convention on Climate Change and other international collaborations to reduce greenhouse gas (GHG) intensity and missions.

In the USA, a programme timeline has been set to demonstrate a portfolio of safe, cost effective GHG capture, storage and mitigation technologies at the commercial scale by 2012, under the close supervision of the National Energy Technology Laboratory (NETL). It is hoped that such a programme will lead to substantial deployment and market penetration, and help to slow GHG emissions in the near-term, while providing the potential for ultimately stabilizing and reducing emissions in the US.

NETL is funding a number of schemes principally aimed at lowering the cost and energy penalty associated with CO2 capture and improving the understanding of factors affecting CO2 storage permanence. By next year, the NETL has set a goal of beginning a demonstration large-scale storage project that will not only capture and save a million tonnes a year of CO2, but also include enhanced oil and gas recovery, along with enhanced methane gas recovery.

Capture and products recovery

Los Angeles-based Geo-Processors USA, announced earlier this year that it had completed the development of an innovative CCS technology following successful initial process trials in Australia.

The technology - identified as a carbon capture and products recovery (CCPR) system - enables efficient capture of CO2 from ambient air or point-sources and then conversion to useful mineral byproducts for industrial use or recycling. Central to this breakthrough technology is the beneficial use of massive volumes of bicarbonate-rich water produced as waste by oil and gas production, coal mining and coal power stations and desalination processes, and is currently a source of significant environmental concerns and operational costs to these industries.

A typical CCPR system commences with treatment of the alkaline-produced water using cheap lime to generate a caustic spent water and a useful by-product. The caustic spent water is brought into contact with CO2 of ambient air (or from a point-source, such as a power plant) and then reacted again with lime to regenerate calcium carbonate and an alkaline water, which is suitable for the next round of CO2 capture.

This system is a closed-loop because beyond the first reaction step a steady-state chemical situation is set up, enabling the repetition of the CO2 capture-calcium carbonate precipitate cycle. Depending on the scale and number of cycles applied in each case, the spent water from the last reaction step can be either treated to recover other valuable byproducts or converted to dry salt for landfill disposal.

The by-products recovery steps may include production and recycling of calcium oxide. The co-generated high-grade CO2 gas from the calcining step may be partly used in the process for production of a high-value mineral product and the unused portion sold for other industrial applications or sequestrated.

The political angle

Carbon emissions are an issue that is climbing up the political agenda worldwide, and coal, gas and power companies are responding, or leading the search to find ways of reducing CO2. At present, coal provides more than 50 per cent of the electricity in the United States and provides more than two and a half centuries of energy security. Coal used for electricity generation has tripled since 1970, while emissions from coal have been reduced by a third.

Two years ago, some of the world’s biggest coal companies and electric utilities came together with the US Department of Energy to form the FutureGen Industrial Alliance, a non-profit organization to search for new ways of mitigating carbon emissions. They include the giant American power groups, American Electric Power and Southern Company, and the mining groups BHP Billiton and Rio Tinto.

The purpose of the coalition is to demonstrate advanced coal-based technologies to generate electricity and to produce hydrogen to power fuel cells for transportation and other energy needs. The technology is also intended to integrate the capture of carbon emissions with sequestration, helping to address the issue of climate change as energy demand continues to grow worldwide. The 275 MW plant will be developed through a public-private partnership led by the seven founding FutureGen Industrial Alliance members.

In May of this year, the alliance released its initial concept design report (ICDR) for the FutureGen project, a first-of-its-kind power plant with near zero emissions. The ICDR outlines a clear set of project objectives, a conceptual design basis, cost estimates and schedule for the project. The ICDR outlines a carbon sequestration strategy that will use cutting-edge technologies for modeling, monitoring, measuring and verification of CO2 injection into deep geologic formations.

Included in the study is an analysis of capital and operating costs of future plants that could lead to a significant reduction in the cost of electricity produced from coal stations with carbon capture. Currently, four sites are being considered for the project - two in Illinois and two in Texas. A final decision on where the plant is to be located is expected at the end of 2007.

The plant will provide a platform for researchers to test new and innovative technologies. It will gasify coal through a process that converts the coal’s carbon to a synthesis gas composed of hydrogen and carbon monoxide. The synthesis gas will react with steam to produce additional hydrogen and a concentrated stream of carbon dioxide.

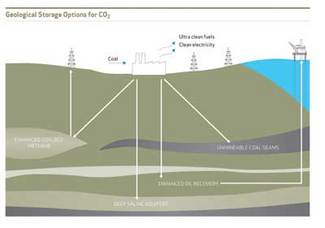

The hydrogen will be used as a clean fuel for electricity generation in turbines, fuel cells or hybrids of these technologies. The captured CO2 will be separated from the hydrogen and permanently sequestered in deep, unmineable coal seams, deep saline aquifers or other geologic formations. Carbon sequestration activities will be monitored over time to assess their effectiveness and potential applicability in various settings around the globe.

CCS - a truly global challege

In Australia too CCS is attracting attention. In 2004, the Australian government produced a White Paper entitled ‘Securing Australia’s Energy Future’, which backed the use of clean coal technology with coal from indigenous reserves. The Australians will provide $500 million for a Low Emission Technology fund to help develop cleaner options. One result of this initiative is the formation of ZeroGen, a demonstration project that will investigate the viability of integrating coal based gasification and CCS to produce low emissions baseload electricity.

Schematic of options for geological options for CO2 (source: World Coal Institute) |

Australia would like ZeroGen to be the first in the world to combine both coal-based gasification and CCS in deep saline aquifers at a commercial scale. It would be a key contributor to national and international efforts to find technological solutions to global warming. The integrated gasification combined cycle (IGCC) and CCS facility will, it is believed, afford deep cuts in CO2 emissions in a country that is one of the world’s largest coal producers.

Further afield, the UK is leading the EU Near-Zero Emissions Coal (NZEC) initiative in China and is actively pursuing a similar project in India. NZEC is proceeding well and will by the end of 2008 identify options for the demonstration of CCS for coal-fired power generation by 2020. The UK has committed £3.5 million ($4.1 million) to the project and is actively pursuing contributions from other members states and the EU for further phases of development.

Snatching defeat from the jaws of victory

Back in Britain, the race to be first with a low emissions CCS project seems lost. UK Carbon Capture and Storage Consortium (UKCCSC) spokesman, Stuart Haszeldine, who is professor of geology at Edinburgh University and a member of the UK Energy Research Centre’s carbon capture and storage programme (CCS), believes the White Paper released earlier this year is a lost opportunity to build on the urgency arising from the Stern Report of October 2006.

Haszeldine said he regretted the government’s lack of urgency in encouraging CCS technology in the wake of the Review. In particular he would like to see incentives offered to energy companies, possibly along the lines of those offered by the Renewables Obligation, in which suppliers are required to source a proportion of their energy from renewable technologies such as wind power. In the same way, suppliers could be required to provide energy which is derived, in part at least, from decarbonized fuel. In addition, he said, financial instruments were needed to set carbon prices at a level that would favour GHG saving measures.

Recent years have seen UK companies keen to set the pace in developing CCS technology. Although Britain’s experience of CO2 capture has been confined to the oil business, it is strong in sub-surface evaluation and geo-engineering technologies as a result of four decades of North Sea experience. But Haszeldine believes the UK may have bungled the opportunity to build a world lead in low carbon technologies. He says the lost momentum is especially worrying since the key legal barriers to burying CO2 beneath the sea bed have - or are being - removed.

Successful amendments to the London Protocol, a marine environment convention restricting carbon capture and storage beneath the sea, were secured in November last year, clearing the way to store CO2 under the sea bed. Similarly, the UK was last month working towards an amendment to the Oslo-Paris (OSPAR) convention which governs North East Atlantic waters and restricts CCS development there.

The UK is also leading on getting CCS recognized in the EU Emissions Trading Scheme (ETS). The European Commission has indicated inclusion in Phase III and has left the option open for Phase II, which will assist with the eventual deployment economics for CCS in the EU. In the wider United Nations Framework Convention on Climate Change (UNFCCC) context, the UK also supports recognition of CCS in the Clean Development Mechanism (CDM) to assist uptake of this technology in developing countries.

In addition, the UK and Norway have established a task force to establish the underlying principles for CO2 storage, which would form the basis for a future regulatory regime. It is planned to extend this task force to cover other countries on the North Sea rim. Norway’s prime minister Jens Stoltenberg and the then UK chancellor, Gordon Brown announced a study to look at joint infrastructure in the North Sea. It will analyze the appropriate framework and value chain which can establish a CO2 network in the region.

Power Engineering International September, 2007Author(s) : Chris Webb

Copyright © 2007: PennWell Corporation, Tulsa, OK; All Rights Reserved. To subscribe or visit go to: http://pepei.pennnet.com