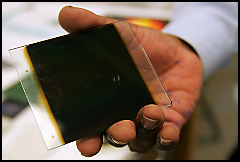

Chris Schneider © The Rocky

Chris Schneider © The Rocky W.S. Sampath holds a small version of a solar panel developed by his startup company, AVA Solar Inc. Sampath has developed a method for making low-cost, high-efficiency solar panels. AVA Solar plans to start production by the end of next year and employ up to 500.

AVA Solar Inc. is gearing up to mass-produce a "low-cost" solar panel based on production technology spun out from CSU research.

The Fort Collins company is being touted as the largest new "primary employer" in northern Colorado in two decades.

"As far as a new company to the region, it's the largest I can recall having in quite a long time," said Eric Holsapple, chairman of the Northern Colorado Economic Development Corp. and a partner with Loveland Commercial, a Loveland real estate development firm.

Local economic development officials have been touting northern Colorado as a solar energy hub.

Fort Collins claims to have about 60 "clean energy" businesses that employ nearly 500. Gov. Bill Ritter also has touted renewable energy as a cornerstone of his energy policy.

AVA Solar's factory is slated to be operational by the end of 2008 and ultimately will employ "definitely in the hundreds," said Russ Kanjorski, AVA Solar's director of strategic planning.

The facility will transform ordinary window glass into solar panels that can provide power to homes and businesses around the globe at about the same cost as traditionally generated electricity, according to CSU.

While they expect to locate the plant in the Fort Collins-Loveland area, company officials haven't nailed down a site.

"Our hope is we can find something that works for the community and the company and put it right here," Kanjorski said.

A pilot plant is under construction at AVA Solar's Fort Collins headquarters and is set to be operational by the end of 2007.

The larger factory's annual production of solar panels is expected to be equivalent to the number necessary to generate 200 megawatts of electricity. That amount of electricity would power 40,000 homes.

Company officials calculate their solar panels will be produced at a cost of less than $1 per watt of electricity, or a third the cost of the current leading solar technology, which relies on semiconductor-grade silicon.

AVA Solar's technology relies on a continuous automated manufacturing process. Two sheets of glass encapsulate a thin film of cadmium telluride, resulting in a 16-inch-by-16-inch solar panel.

Ron Larson, founder of the Colorado Renewable Energy Society and a solar energy analyst, called AVA Solar's formation and new factory "great news."

"Their promise of being the world's lowest-cost producer is very welcome - as prices have recently been high because of limited supply," Larson said.

AVA Solar's patented production process was developed by W.S. Sampath, a CSU mechanical engineering professor. He spent the past 16 years perfecting the technology.

Sampath - along with two affiliate faculty members and former students of his, Kurt -Barth and Al Enzenroth - formed AVA Solar in January to commercialize the technology.

General Electric approached the three about licensing the technology, but the founders opted to spin off the manufacturing process into a startup business.

AVA Solar has raised "tens of millions" of dollars in venture capital funding, Kanjorski said.

It also was recently awarded a $3 million grant from the U.S. Department of Energy's Solar America Initiative.

AVA Solar Inc.

• Headquarters: Fort Collins

• New factory: Expected to be located in Fort Collins-Loveland area and operational by the end of 2008

• Jobs: Up to 500. Peak employment expected to occur in the first half of 2009.

• Product: Solar panels produced via a "low-cost" manufacturing process

Availability

Solar panel initially will be available to commercial developers by end of 2008. Consumer availability expected after 2009.

• Estimated cost of installation: $12,000 for a large home, on top of the cost of solar panels. Price of panels still to be determined.

• Estimated cost of power from panels: 10 cents to 15 cents per kilowatt hour, or about equal to the cost of electricity from traditional power grid in many parts of the nation. Existing solar panels, by comparison, cost 20 cents to 30 cents per kilowatt hour.Source: Ava Solar

fillionr@RockyMountainNews.com or 303-954-2467

To subscribe or visit go to: http://www.rockymountainnews.com