Valerie Thompson

EE Times Europe

02/13/2008 1:50 PM

ZURICH, Switzerland — Engineers the world over are used to optimizing for

size, cost, reliability and power consumption. They are also used to a

relatively free-hand in how to make those optimizations and how to weigh

different factors – say the brightness and look of a display versus power

consumption; or the way power management works to save power in standby

mode.

Now the European Union is getting involved with its ecodesign initiative.

And like previous initiatives such as those on the handling of

electromagnetic interference, the handling of waste equipment (WEEE) and

RoHS and REACH in the area of materials, if companies do not pay attention

to the requirements they will not be allowed market their products within

the European Union.

So questions of design will not only be issues of performance versus cost

but may involve additional cost for the sake of reaching mandatory

environmentally-oriented benchmarks. This is also likely to extend to a

requirement placed upon vendors to "educate" users through documentation put

out with products.

For two years the European Union has been investigating and consulting

following a July 2005 decision to address almost all energy-using products (EuP)

on the market with Ecodesign regulations. So far the initiative covers about

20 product categories including desktop and laptop computers and computer

monitors, televisions, set-top boxes, copiers, faxes, printers, scanners,

multifunction devices with a phased introduction of regulations over the

next two years.

The main drive behind the legislation is a desire within the European Union

to bear down on power consumption and green house gas emissions. As the

directive says, "The ecodesign of products . . . provides new opportunities

for manufacturers, for consumers and for society as a whole."

While the final implementing measures and exact timelines covering the first set of products covered by the EuP Directive have not come into effect, it is important to be up to speed, since it affects CE marking, consumer-facing labels, and certain documentation requirements.

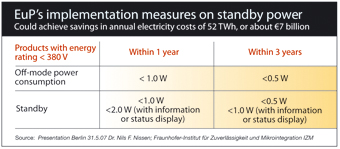

And once the EuP measures are adopted the timelines are tight, according to Aidan Turnbull of Environ U.K. Ltd. (Corsham, England), a consulting firm specializing in environmental and health science regulation, in an online presentation, pointing to requirements for standby-mode power consumption. The full force of that legislation comes in over a three-year span to take values down to half what they are in the first year for such products as cordless phones, DVD players, PCs, ovens, fax machines, electric toothbrushes, and printers – see table.

The main and initial thrust of the legislation is on power saving in standby-mode because this is where the most gains can be made. According to some estimates the EuP standby measures could achieve savings of 52-terawatthours, worth about €7 billion (about $10 billion) in electricity costs per year.

Nonetheless the EuP preparatory report on PCs, published in September 2007, considers power savings in the processor and on the motherboard including a discussion of the benefits of multicore processors. For now software is excluded from the discussion although the opportunity for power-saving through improved software writing is noted. Microsoft’s Vista operating system is given a tepid welcome in the report, because of the way it wastes computer cycles negating any benefits from improved power management facilities.

One premise of the EuP legislation is that 80 percent of all product-related environmental impacts are determined during the design phase of a product. The EuP requirements are generally laid down in terms of "best available technology" and "least cost" a method commonly used by EU directives which means that components, chips, and technologies are available to support the new constraints.

"Engineers are already being asked to apply their scientific background to reduce waste and hazardous materials use [RoHS and WEEE]. Now they need to consider energy efficiency. It is about thinking of the impact of a product across the lifecycle, a mindset," said Turnbull.

Constantin Herrmann, of consultancy PE International GmbH (Leinfelden-Echterdingen, Germany), spent most of 2007 in Taiwan, China, Japan and Korea, making presentations on EuP. Awareness and interest in these countries is stronger than in Europe, he said, although this may reflect those countries’ status as the world’s electronics factory. Herrmann said that the implementation of other EU directives, such as RoHS showed that a lead time of 18 to 24 month is necessary to get companies up to speed.

"The industry, bracing itself for another shattering new set of regulations after WEEE/RoHS and REACH, was very eager to look for concrete information on this directive, which would sway their new product development in coming years," said Derek Lam, a corporate marketing and business development executive at consultancy SGS Hong Kong Ltd.

SGS, which provides training and seminars on quality assurance, teamed with overseas experts in EuP research to provide first-hand insights on the directive and hosted a series of seminars on the topic in China, Taiwan and Hong Kong last year. According to Lam, the seminars drew "tremendous responses" from clients.

Mark Goedkoop, owner of Pré Consultants (Amersfoort, The Nethelands), said that while overall the business has been growing steadily, he has noticed an uptick in demand for information on EuP in the past twelve months. Goedkoop said electronics-related industry associations have taken it upon themselves to acquire his firm’s software and training to assist smaller members.

But one area where he has not seen much interest is amongst European importers. "Importers are responsible for ensuring the products they import comply. They will at the least need to provide an ecodesign dossier [documentation]," said Goedkoop.

Electronics manufacturers are facing two different types of requirements. One is where energy-usage is the key factor. "Currently the compliance-needs tend to be purely technical related. They are based on specific implementing measures - threshold values and limits to cope with, such as minimum standby power consumption," commented Herrmann of PE International.

The other more complex requirement is where manufacturers have to show that product designers have reduced key environmental performance indicators compared with previous products .

Additional reporting by Peter Clarke.

Copyright © 2006 CMP Media LLC , EETimes EU Copyright. All rights reserved. To subscribe or visit go to: http://www.eetimes.eu