Welcome to the Revolution: Emanuel Sachs and Frank van Mierlo

Tulsa -- Solar at the cost of coal. Sounds like the punch line to a joke, some might say. How can solar energy–with its reputation for high cost–compete with baseload coal, still the dominant fuel for U.S. electric power generation?

But spend time talking with Frank van Mierlo and Emanuel Sachs, principals at 1366 Technologies based near Boston, and their conviction shines through: solar just may be able to reach grid parity with coal, and sooner than you may think.

“I

truly believe it’s doable,” says Sachs, pictured left. “I

believe it’s even doable without assigning a cost to carbon.”

“I

truly believe it’s doable,” says Sachs, pictured left. “I

believe it’s even doable without assigning a cost to carbon.”

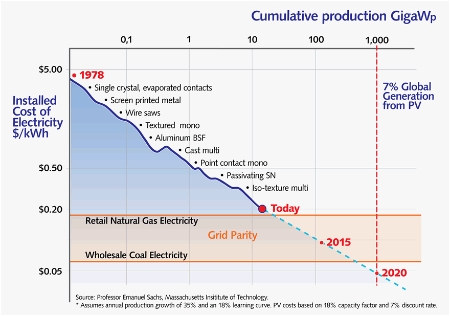

Strong stuff, but 1366 is working on disruptive technologies and incremental improvements to existing technologies that could, once fully commercialized, drive down the cost of silicon-based photovoltaic cells. Sachs says the key measure is grid parity and that solar PV is approaching costs comparable to natural gas-fired peaking units.

“What more tipping point do you need? Just do the projections,” van Mierlo says, referring to numbers that show solar PV markets growing by 30 percent to 40 percent a year. He expects solar to be cost competitive within 10 years. Only in hindsight, he says, will it be understood the “revolution” was already underway in 2010. “We will say it was so obvious.”

But the revolution was anything but obvious in 1986. That was when Sachs set aside his work in PV as funding dried up, the result of falling oil prices and waning federal support. Sachs had scored an early success with his academic research, inventing string ribbon technology as part of his MIT Ph.D thesis. He enjoyed the novel experience of seeing technologies developed in his thesis adopted by two firms that went on to make flexible PV sheets.

But when PV funding dried up in the mid-’80s, Sachs turned his focus toward rapid prototyping process controls for integrated circuit manufacturing. One outcome was his invention of 3-D printing. Van Mierlo, himself an MIT graduate, was also busy launching startup companies. A primary venture made automated underwater robotic submarines. These used artificial intelligence to map mines in the ocean for the Defense Department.

Then came the terrorist attacks of September 11, which changed the outlook of both men.

“As a consequence of 9/11 I said ‘energy, energy, energy,’” Sachs says. For perhaps the only time since the early 1970s, Americans began to understand the danger of “sending unprecedented amounts of wealth” to oil-rich countries that “resent us,” Sachs says. On Sept. 12, 2001, Sachs says he began winding down his MIT work on 3-D printing and planning his return to PV.

Five years later, van Mierlo (right) met Sachs and told the

inventor how impressed he was with his work; so impressed that

he would work for Sachs for free to help commercialize a

light-capturing ribbon technology.

“Often decisions are based on price and if it goes to zero it can be attractive,” van Mierlo recalls of his sweat-equity offer. Over the next 8 months the two found they could work together, so in September 2007 they founded 1366 Technologies. Shortly thereafter they closed “A-round” financing with Northbridge Investment Partners and Polaris as venture capital providers.

The company’s numeric name acknowledges the fact that sunlight falls on the earth at the rate of 1,366 Watts per square meter. That means 130,000 TW of solar energy reaches the Earth each year. The company also figures that humans consume coal, nuclear and natural gas at the rate of around 15 TW a year, a fraction of the sun’s delivered energy potential.

Silicon, the company’s material of choice for making PV cells, is relatively abundant on earth. After oxygen, silicon is the most-common element in the Earth’s crust, making up more than 25 percent by mass. Silicon is also the foundation of commercial products such as computer chips, glass, steel, cement and lubricants, and can be found in toothpaste and ketchup.

Silicon is also a good semiconducting material. Silicon cells have proven efficiencies above 23 percent in manufacturing, with a theoretical potential of around 30 percent.

In additon to silicon’s efficiency, a no-less-potent driver for 1366 is PV’s relative simplicity. It literally has no moving parts. That’s important to Sachs and van Mierlo who consider complex systems like nuclear power plants and deepwater oil drilling as vulnerable to accidents. Sachs calls such ventures “Technology Towers of Babel” and says “we are assuming things built by humans can be perfect and can operate perfectly.” In reality, “remarkably insane things” happen all the time.

Van Mierlo agrees and suggests a lesson from the BP oil spill in the Gulf of Mexico is not to oppose drilling so much as to oppose nuclear power.

“Maybe as the human race we should not do stuff where the cost of failure is so enormous,” he says. The consequences of a nuclear accident would likely be much greater than an oil spill. As a result, 1366 Technologies’ work focuses on designing PV systems that are simple to operate and whose adverse consequences are tolerable.

The company is advancing two technologies for multi-crystalline silicon solar cells. First, it addressed cell texture, creating a honeycomb structure that introduces cross-textured surfaces to the cell. The company claims the improvement can trap more light and enable up to 1 percent higher absolute efficiency overall than previous cell designs.

A second technology focuses on front-side cell metallization. This reduces finger line widths from 120 microns to 30 microns and includes a grooved ribbon busbar. The company contends that in contrast to industry-standard thick fingers and flat busbars, which typically shade 9 percent of a cell’s front surface, its approach shades 2 percent of the cell and delivers 75 percent of the efficiency gains of back-contact designs. As a result, a 15 percent efficient cell may become more than 16 percent efficient. That’s a seemingly small step unless one considers the power of aggregated improvement.

To illustrate, van Mierlo says today’s PV production is around 10 GW. Assuming $1 a watt, a 1 percent absolute efficiency improvement represents approximately $700 million in the $10 billion market.

“Put in that light, it becomes significant,” van Mierlo says of the efficiency improvement 1366 is working to commercialize.

A third, potentially disruptive technology advancement, is Sach’s invention of an improved silicon wafer manufacturing process. Current production requires up to four steps, including cutting and grinding, which can lead to losing as much as half the silicon that is used to make each wafer. Sach’s invention of a direct wafer process plucks the silicon directly away from the melt. Once the process becomes commercial, the approach could cut wafer production costs by up to two-thirds. And that, in turn, would hasten the day when solar reaches grid parity with coal.

In pursuing that goal, 1366 Technologies focuses on improving processes in much the same way Alastair Pilkington and Kenneth Bickerstaff improved glassmaking in the 20th century, or Henry Bessemer improved steelmaking in the 19th.

Bessemer didn’t invent steel; the Romans had steel, van Mierlo says. What Bessemer did – and what 1366 Technologies aims to achieve – was to invent a process that cut production costs by 80 percent.

Seen in that light, solar at the cost of coal may not be so far-fetched after all.

To subscribe or visit go to:

http://www.renewableenergyaccess.com

To subscribe or visit go to:

http://www.renewableenergyaccess.com