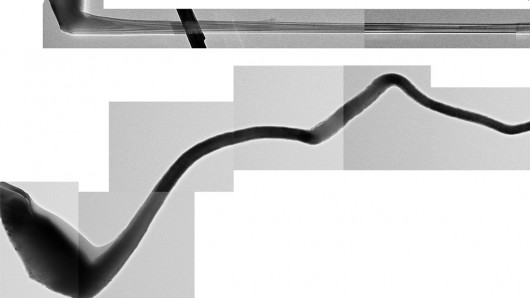

Formerly unobserved increase in length and twist of the anode in a nanobattery (Image: DOE Center for Integrated Nanotechnologies)

Because battery technology hasn’t developed as quickly as the electronic devices they power, a greater and greater percentage of the volume of these devices is taken up by the batteries needed to keep them running. Now a team of researchers working at the Center for Integrated Nanotechnologies (CINT) has created the world’s smallest battery, and although the tiny battery won’t be powering next year’s mobile phones, it has already provided insights into how batteries work and should enable the development of smaller and more efficient batteries in the future.

The tiny rechargeable, lithium-based battery was created by a team led by Sandia National Laboratories researcher Jianyu Huang. It consists of a bulk lithium cobalt cathode three millimeters long, an ionic liquid electrolyte, and has as its anode a single tin oxide (Sn02) nanowire 10 nanometers long and 100 nanometers in diameter – that’s one seven-thousandth the thickness of a human hair.

Because nanowire-based materials in lithium-ion batteries offer the potential for significant improvements in power and energy density over bulk electrodes the researchers wanted to gain an understanding of the fundamental mechanisms by which batteries work. They therefore formed the battery inside a transmission electron microscope (TEM) so they could study the charging and discharging of the battery in real time and at atomic scale resolution.

By following the progression of the lithium ions as they travel along the nanowire, the researchers found that during charging the tin oxide nanowire rod nearly doubles in length. This is far more than its diameter increases and could help avoid short circuits that may shorten battery life. This unexpected finding goes against the common belief of workers in the field that batteries swell across their diameter, not longitudinally.

“Manufacturers should take account of this elongation in their battery design,” Huang said. “These observations prove that nanowires can sustain large stress (>10 GPa) induced by lithiation without breaking, indicating that nanowires are very good candidates for battery electrodes,” he added.

Atomic-scale examination of the charging and discharging process of a single nanowire had not been possible before because the high vacuum in a TEM made it difficult to use a liquid electrolyte. Huang’s group overcame this problem by demonstrating that a low-vapor-pressure ionic liquid – essentially molten salt – could function in the vacuum environment.

This means that although the work was carried out using tin oxide nanowires, Huang says the experiments could be extended to other materials systems, either for cathode or anode studies.

“The methodology that we developed should stimulate extensive real-time studies of the microscopic processes in batteries and lead to a more complete understanding of the mechanisms governing battery performance and reliability,” he said. “Our experiments also lay a foundation for in-situ studies of electrochemical reactions, and will have broad impact in energy storage, corrosion, electrodeposition and general chemical synthesis research field.”

The research team’s work is reported in the December 10 issue of the journal Science.

Copyright © gizmag 2003 - 2010 To subscribe or visit go to: http://www.gizmag.com