by Neal Singer, Sandia National Labs

[From RenewableEnergyWorld.com]

Sandia National Laboratories scientists have developed tiny glitter-sized photovoltaic cells that could revolutionize the way solar energy is collected and used.

The tiny cells could turn a person into a walking solar battery charger if they were fastened to flexible substrates molded around unusual shapes, such as clothing.

The solar particles, fabricated of crystalline silicon, hold the potential for a variety of new applications. They are expected eventually to be less expensive and have greater efficiencies than current photovoltaic collectors that are pieced together with 6-inch- square solar wafers.

The cells are fabricated using microelectronic and microelectromechanical systems (MEMS) techniques common to today’s electronic foundries.

Sandia lead investigator Greg Nielson said the research team has identified more than 20 benefits of scale for its microphotovoltaic cells. These include new applications, improved performance, potential for reduced costs and higher efficiencies.

“Eventually units could be mass-produced and wrapped around unusual shapes for building-integrated solar, tents and maybe even clothing,” he said. This would make it possible for hunters, hikers or military personnel in the field to recharge batteries for phones, cameras and other electronic devices as they walk or rest.

Even better, such microengineered panels could have circuits imprinted that would help perform other functions customarily left to large-scale construction with its attendant need for field construction design and permits.

Said Sandia field engineer Vipin Gupta, “Photovoltaic modules made from these microsized cells for the rooftops of homes and warehouses could have intelligent controls, inverters and even storage built in at the chip level. Such an integrated module could greatly simplify the cumbersome design, bid, permit and grid integration process that our solar technical assistance teams see in the field all the time.”

For large-scale power generation, said Sandia researcher Murat Okandan, “One of the biggest scale benefits is a significant reduction in manufacturing and installation costs compared with current PV techniques.”

Part of the potential cost reduction comes about because microcells require relatively little material to form well-controlled and highly efficient devices.

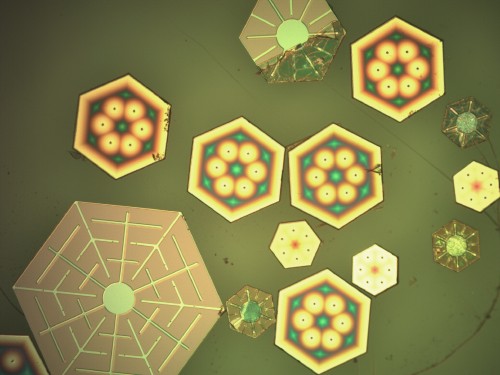

From 14-20µm thick (a human hair is approximately 70µm thick), they are 10× thinner than conventional 6-inch-by-6-inch brick-sized cells, yet perform at about the same efficiency.

|

| Representative thin crystalline-silicon photovoltaic cells, 14-20µm thick and 0.25-1mm across. (Source: Sandia Labs, image by Murat Okanadan) |

100 times less silicon generates same amount of electricity

“So, they use 100× less silicon to generate the same amount of

electricity,” said Okandan. “Since they are much smaller and have fewer

mechanical deformations for a given environment than the conventional

cells, they may also be more reliable over the long term.”

Another manufacturing convenience is that the cells, because they are

only hundreds of micrometers in diameter, can be fabricated from

commercial wafers of any size, including today’s 300mm (12-inch)

diameter wafers and future 450mm (18-inch) wafers. Further, if one cell

proves defective in manufacture, the rest still can be harvested, while

if a brick-sized unit goes bad, the entire wafer may be unusable. Also,

brick-sized units fabricated larger than the conventional

6-inch-by-6-inch cross section to take advantage of larger wafer size

would require thicker power lines to harvest the increased power,

creating more cost and possibly shading the wafer. That problem does not

exist with the small-cell approach and its individualized wiring.

Other unique features are available because the cells are so small. “The

shade tolerance of our units to overhead obstructions is better than

conventional PV panels,” said Nielson, “because portions of our units

not in shade will keep sending out electricity where a partially shaded

conventional panel may turn off entirely.”

Because flexible substrates can be easily fabricated, high-efficiency PV

for ubiquitous solar power becomes more feasible, said Okandan.

A commercial move to microscale PV cells would be a dramatic change from

conventional silicon PV modules composed of arrays of 6-inch-by-6-inch

wafers. However, by bringing in techniques normally used in MEMS,

electronics and the light-emitting diode (LED) industries (for

additional work involving gallium arsenide instead of silicon), the

change to small cells should be relatively straightforward, Gupta said.

Each cell is formed on silicon wafers, etched and then released

inexpensively in hexagonal shapes, with electrical contacts

prefabricated on each piece, by borrowing techniques from integrated

circuits and MEMS.

Offering a run for their money to conventional large wafers of

crystalline silicon, electricity presently can be harvested from the

Sandia-created cells with 14.9%efficiency. Off-the-shelf commercial

modules range from 13% to 20% efficient.

A widely used commercial tool called a pick-and-place machine — the

current standard for the mass assembly of electronics — can place up to

130,000 pieces of glitter per hour at electrical contact points

preestablished on the substrate; the placement takes place at cooler

temperatures. The cost is approximately one-tenth of a cent per piece

with the number of cells per module determined by the level of optical

concentration and the size of the die, likely to be in the 10,000 to

50,000 cell per square meter range. An alternate technology, still at

the lab-bench stage, involves self-assembly of the parts at even lower

costs.

Solar concentrators — low-cost, prefabricated, optically efficient

microlens arrays — can be placed directly over each glitter-sized cell

to increase the number of photons arriving to be converted via the

photovoltaic effect into electrons. The small cell size means that

cheaper and more efficient short focal length microlens arrays can be

fabricated for this purpose.

High-voltage output is possible directly from the modules because of the

large number of cells in the array. This should reduce costs associated

with wiring, due to reduced resistive losses at higher voltages.

Other possible applications for the technology include satellites and

remote sensing.

The project combines expertise from Sandia’s Microsystems Center;

Photovoltaics and Grid Integration Group; the Materials, Devices, and

Energy Technologies Group; and the National Renewable Energy Lab’s

Concentrating Photovoltaics Group.

Involved in the process, in addition to Nielson, Okandan and Gupta, are

Jose Luis Cruz-Campa, Paul Resnick, Tammy Pluym, Peggy Clews, Carlos

Sanchez, Bill Sweatt, Tony Lentine, Anton Filatov, Mike Sinclair, Mark

Overberg, Jeff Nelson, Jennifer Granata, Craig Carmignani, Rick Kemp,

Connie Stewart, Jonathan Wierer, George Wang, Jerry Simmons, Jason

Strauch, Judith Lavin and Mark Wanlass (NREL).

The work is supported by DOE’s Solar Energy Technology Program and

Sandia’s Laboratory Directed Research & Development program, and has

been presented at four technical conferences this year.

The ability of light to produce electrons, and thus electricity, has

been known for more than a hundred years.

The article was written by Neal Singer, a science writer at Sandia

National Laboratories. His freelance articles have appeared in Science,

Smithsonian, Scientific American, the World and I, and other magazines.

Copyright © 2009: PennWell Corporation To subscribe or visit go to:

http://www.electroiq.com