New materials could soak up carbon emissions

By Ben Coxworth

17:36 June 1, 2010

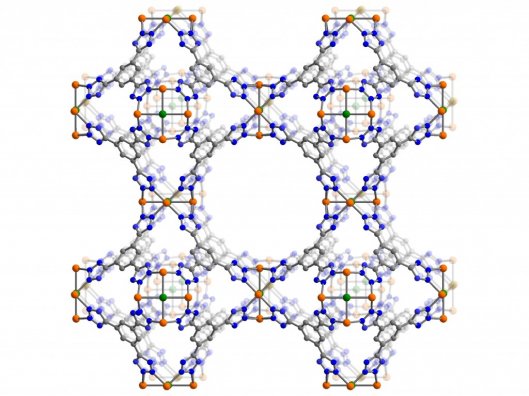

Imagine a material that appears to be the size of a sugar cube, but when you unfold it, you discover it has the surface area of a football field. Besides its unbelievable surface area, this substance can also be tweaked to absorb specific molecules. Such materials are called metal-organic frameworks, and could be ideal candidates for filtering the carbon out of smoke stack emissions. With that end in mind, a team of California chemists are now racing to create a metal-organic framework that can be used in an industrial carbon sponge. Because there are millions of possible molecular variations, the team is using development techniques that are up to 100 times faster than conventional methods.

The project is being led by Jeffrey Long, a chemist at the University of California’s Lawrence Berkeley National Laboratory. His team has designed an automated robotic system that simultaneously synthesizes hundreds of metal-organic frameworks. These materials will be subjected to X-ray diffraction, followed by magnetic resonance spectroscopy, to see if they have the pore size distribution necessary for carbon capture. The materials that pass that test will go on to a high-throughout gas sorption analysis, to determine how well they could actually remove carbon dioxide from flue gas.

A computer algorithm will munch on the obtained data, and apply its output to the next round of test materials. Researchers will also assess promising materials, to see if they would be economically-feasible for large-scale use. Utilizing this system, Long’s team hopes to have a suitable material ready in no more than three years.

When used at power plants, existing carbon sponges are a bit of a compromise. Liquid amine scrubbers, for instance, sap up to 30% of the power created at the plant. Long hopes to discover a material that only takes off 10%. “We need to find the optimum range of metal-organic frameworks for each power plant,” he said. “Ultimately, this research is intended to lead to materials worthy of large-scale testing and commercialization.”

Copyright © gizmag 2003 - 2010 To subscribe or visit go to: http://www.gizmag.com