Scientists create inexpensive new thermoelectric material

By Ben Coxworth

November 28, 2012

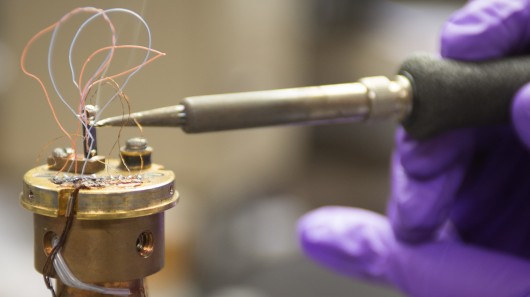

A test of the new material, being conducted at Michigan State University's Center for Revolutionary Materials for Solid State Energy Conversion

Wherever there’s enough of a temperature gradient between two surfaces, thermoelectric materials can be used to generate an electric current. If a coat were made with thermoelectric felt, for instance, a current could be generated by exploiting the difference between the wearer’s body heat and the cold outdoor air. Now, scientists have developed an inexpensive new type of thermoelectric material, that could make the technology more commercially viable.

The material was developed by a team from Michigan State University, led by Prof. Donald Morelli. Although synthetic, its composition is based on that of a family of naturally-occurring and vastly-abundant minerals known as tetrahedrites. That composition has been tweaked just slightly, to make the finished product thermoelectric.

The production process involves grinding “very common materials” into a powder, then using a combination of heat and pressure to compress them into the sizes needed.

Although some other materials are more efficient at converting temperature gradients into electricity, Morelli maintains that many of those are unfit for practical use because their components are rare or toxic, or they’re too expensive to synthesize.

“Typically you’d mine minerals, purify them into individual elements, and then recombine those elements into new compounds that you anticipate will have good thermoelectric properties,” he said. “But that process costs a lot of money and takes a lot of time. Our method bypasses much of that.”

It is hoped that the new material could be used to cost-effectively harvest electricity from sources such as vehicle exhaust pipes, industrial power plants, and home furnaces.

A paper on the research was recently published in the journal Advanced Energy Materials.

Source: Michigan State University

About the AuthorCopyright © gizmag 2003 - 2012 To subscribe or visit go to: http://www.gizmag.com