Toward pacemakers powered by heartbeats

10/17/2012 8:24 AM EDT

S. Boisseau1, J.J. Chaillout1, M. Deterre2 and R. Dal Molin2

1. CEA-LETI, Minatec Campus, Grenoble, France

2. Sorin CRM SAS, Clamart, France

Heart diseases are a major and growing public health concern, affecting millions of people and costing tens of billions of dollars each year. Among them, arrhythmias are one of the most common heart disorders but can be quite easily treated by using pacemakers.

The first pacemaker implantation dates back to 1958, and obviously, many improvements have been performed since then, making these devices safer and more comfortable. Yet, researchers and medical groups want to go further, and imagine today the pacemakers of the future, relying on Micro-Electro-Mechanical Systems (MEMS) technologies. Smaller and smarter, these devices will reduce costs and further improve patients' comfort and safeness.

1. Pacemakers, market and needs for improvements

Pacemakers have been used for years, delivering electrical impulses to regulate the beating of the heart. Today, more than 3 million people worldwide have pacemakers and about 1’000'000 new devices are implanted each year [1]. Hence, the market of pacemakers is forecasted to reach $5.1 billion in 2018 with an annual growth rate of 11 percent by then [2].

As a consequence, the competition is tough with many players involved (Medtronic, St-Jude, Boston Sc, Sorin Group, Biotronik), and innovation is an excellent lever to gain market shares. The research in this area is today focused on small devices using MEMS technologies, paving the way to technological breakthrough cardiac implants.

Actually, today's pacing systems have two main drawbacks, offering opportunities of improvements and differentiations from the competition [3].

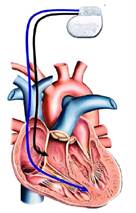

The first major way of improvement concerns the lead. Indeed, present pacemakers are made of two elements (figure 1a):

(i) a pulse generator (the “pacemaker”) , placed under the skin in the chest, that gathers an energy source (battery) and the impulse control system.

(ii) a lead inserted directly in the heart through a vein, delivering the impulses.

As a matter of fact, leads are not always easy to position, may be subject to displacement and erosion, which may lead to conduction or insulation failures.

The second major way of improvement is the pacemaker's battery lifetime. Over the years, various power sources have been used for pacemakers (batteries, plutonium). Unfortunately, these sources are limited and must be replaced every five to ten years, leading to new surgeries to change the pulse generator, and inherent (but preventable) costs.

In fact, size reduction thanks to MEMS devices makes it possible to imagine tiny pacemakers fixed directly on the heart wall (epicardium), limiting the quantity of energy given to the heart at each cycle, paving the way to leadless pacemakers powered by energy harvesting (figure 1b) and therefore solving the problems of leads and autonomy at the same time.

The pacemakers of the future will be small, leadless and everlasting thanks to energy harvesting (EH).

(a)

(b)

Figure 1: (a) current pacemaker and (b) future leadless pacemaker powered by energy harvesting

Since the pacemaker is inserted into the heart, only energy coming from the human body is available. As presented in [4], four ambient sources can theoretically be exploited: radiant sources, thermal sources, mechanical sources and biochemical sources. However, only vibrations and biochemical products are available in the heart, as the body is opaque and thermo-regulated.

Extracting energy thanks to biochemistry is generally complicated and especially in the harsh environment of the body, leading to packaging challenges, that are hard to solve (semi-permeable membranes' lifetimes, clogging).

On the other hand, heartbeat's vibration energy harvesting offers a great opportunity to develop hermetic systems, not in contact with any human body fluids; it was then chosen by HBS consortium (HBS for Heart Beat Scavenger) to power Sorin's future pacemakers.