Champion nano-rust for producing solar hydrogen

Jul 07, 2013

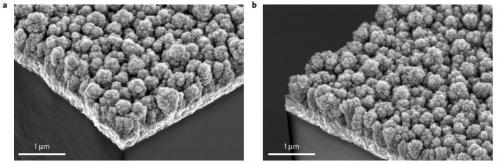

Cross-sectional SEM images show 2L (a) and 6L (b) electrodes from a 45-deg. viewing angle. Credit: Nature Materials, DOI: 10.1038/nmat3684

EPFL and Technion researchers have figured out the "champion" nanostructures able to produce hydrogen in the most environmentally friendly and cheap manner, by simply using daylight.

In the quest for the production of renewable and clean energy, photoelectrochemical cells (PECs) constitute a sort of a Holy Grail. PECs are devices able of splitting water molecules into hydrogen and oxygen in a single operation, thanks to solar radiation. "As a matter of fact, we've already discovered this precious chalice, says Michael Grätzel, Director of the Laboratory of Photonics and Interfaces (LPI) at EPFL and inventor of dye-sensitized photoelectrochemical cells. Today we have just reached an important milestone on the path that will lead us forward to profitable industrial applications."

This week, Nature Materials is indeed publishing a groundbreaking article on the subject. EPFL researchers, working with Avner Rotschild from Technion (Israel), have managed to accurately characterize the iron oxide nanostructures to be used in order to produce hydrogen at the lowest possible cost. "The whole point of our approach is to use an exceptionally abundant, stable and cheap material: rust," adds Scott C. Warren, first author of the article.

At the end of last year, Kevin Sivula, one of the collaborators at the LPI laboratory, presented a prototype electrode based on the same principle. Its efficiency was such that gas bubbles emerged as soon as it was under a light stimulus. Without a doubt, the potential of such cheap electrodes was demonstrated, even if there was still room for improvement.

By using transmission electron microscopy (TEM) techniques, researchers were able to precisely characterize the movement of the electrons through the cauliflower-looking nanostructures forming the iron oxide particles, laid on electrodes during the manufacturing process. "These measures have helped us understand the reason why we get performance differences depending on the electrodes manufacturing process", says Grätzel.

By comparing several electrodes, whose manufacturing method is now mastered, scientists were able to identify the "champion" structure. A 10x10 cm prototype has been produced and its effectiveness is in line with expectations. The next step will be the development of the industrial process to large-scale manufacturing. A European funding and the Swiss federal government could provide support for this last part.

Evidently, the long-term goal is to produce hydrogen – the fuel of the future – in an environmentally friendly and especially competitive way. For Michael Grätzel, "current methods, in which a conventional photovoltaic cell is coupled to an electrolyzer for producing hydrogen, cost 15 € per kilo at their cheapest. We're aiming at a € 5 charge per kilo".

![]() Explore further:

Using rust and water to store solar energy as hydrogen

Explore further:

Using rust and water to store solar energy as hydrogen

More information: Identifying champion nanostructures for solar water-splitting, Nature Materials, DOI: 10.1038/nmat3684

Journal reference:

Nature Materials

![]()

![]()

Provided by Ecole Polytechnique Federale de Lausanne