What are rare earth metals?

They're crucial to hybrid cars, wind turbines and many other

green-tech innovations, but these elusive metals also have

an environmental dark side.

Wed, Jun 22 2011

Permanent

magnets are another big role for rare earths. Their light

weight and high magnetic strength have made it possible to

miniaturize a wide range of electronic parts, including many

used in home appliances, audio/video equipment, computers,

cars and military gear. Innovations like small,

multi-gigabyte jump drives and DVD drives likely wouldn't

exist without rare earth magnets, which are often made from

a neodymium alloy but may also contain

praseodymium,

samarium,

gadolinium or

dysprosium.

Permanent

magnets are another big role for rare earths. Their light

weight and high magnetic strength have made it possible to

miniaturize a wide range of electronic parts, including many

used in home appliances, audio/video equipment, computers,

cars and military gear. Innovations like small,

multi-gigabyte jump drives and DVD drives likely wouldn't

exist without rare earth magnets, which are often made from

a neodymium alloy but may also contain

praseodymium,

samarium,

gadolinium or

dysprosium.

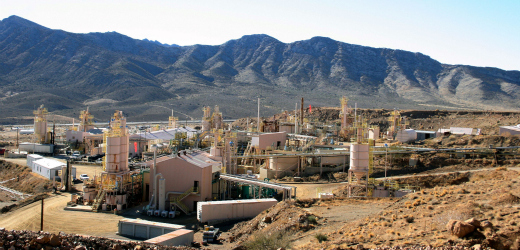

Molycorp

is allowed to deepen its pit at Mountain Pass (pictured) by

an extra 300 feet over the next 30 years, which could boost

global supplies of rare earths by 10 percent a year. And

it's not the only company itching to tap U.S. reserves:

Wings Enterprises is reviving its Pea Ridge mine in

Missouri, for instance, while a new mine in Wyoming may open

as early as 2014. Overall, experts say the growth of rare

earth mining is all but inevitable, adding a toxic asterisk

to many technologies designed to fight climate change.

Molycorp

is allowed to deepen its pit at Mountain Pass (pictured) by

an extra 300 feet over the next 30 years, which could boost

global supplies of rare earths by 10 percent a year. And

it's not the only company itching to tap U.S. reserves:

Wings Enterprises is reviving its Pea Ridge mine in

Missouri, for instance, while a new mine in Wyoming may open

as early as 2014. Overall, experts say the growth of rare

earth mining is all but inevitable, adding a toxic asterisk

to many technologies designed to fight climate change.

"Rare earth" metals aren't as rare as they sound — in fact,

you're probably using some right now. They're key to a

variety of everyday devices, from tablet computers and TVs

to hybrid cars and wind turbines, so it may be encouraging

to know several kinds are actually common.

Cerium, for example, is the 25th most abundant element

on Earth.

So why are they called "rare" earths? The name alludes to

their elusive nature, since the

17 elements rarely exist in pure form. Instead, they mix

diffusely with other minerals underground, making them

costly to extract.

And, unfortunately, that isn't their only drawback. Mining

and refining rare earths makes an

environmental mess, leading most countries to neglect

their own reserves, even as demand soars. China has been the

main exception since the early 1990s, dominating global

trade with its willingness to intensively mine rare earths —

and to deal with their acidic, radioactive byproducts.

That's why the U.S., despite large deposits of its own,

still gets 92 percent of its rare earths from China.

This wasn't a problem until recently, when China began

tightening its grip on rare earths. The country first

imposed trade limits in 1999, and its exports shrank by 20

percent from 2005 to 2009. They then took a dramatic

nosedive in 2010, squeezing global supplies amid a dispute

with Japan, and they've

fallen even further in 2011. China says it's being

stingy for

environmental reasons, not economic leverage, but the

cutbacks have nonetheless caused major price spikes. The

price of

neodymium hit $129 per pound in May, for example, up

from just $19 a year earlier.

Many of China's customers are already shopping around:

Deposits in Russia, Brazil, Australia and South Asia have

drawn widespread interest, as has the only rare earths mine

in the U.S. But even though that mine reopened in April

after a decade-long hiatus — and holds the largest rare

earth deposit outside China — the U.S., like many countries,

doesn't want to be the world's new go-to source for rare

earths. "Diversified global supply chains are essential,"

the Energy Department said in a

2010 report.

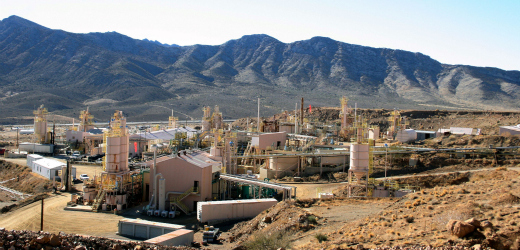

The newly reopened

rare earths mine in Mountain Pass, Calif., pictured here in

December 2010.

Why are so many countries reluctant to exploit their own

rare earth reserves? And what makes rare earths so unique to

begin with? For answers to these and other questions, check

out the following overview of these 17 mysterious metals.

A rare breed

Much of rare earths' appeal lies in their ability to perform

obscure, highly specific tasks.

Europium provides red phosphor for TVs and computer

monitors, for example, and it has no known substitute.

Cerium similarly rules the glass-polishing industry, with

"virtually all polished glass products" dependent on it,

according to the U.S. Geological Survey.

Permanent

magnets are another big role for rare earths. Their light

weight and high magnetic strength have made it possible to

miniaturize a wide range of electronic parts, including many

used in home appliances, audio/video equipment, computers,

cars and military gear. Innovations like small,

multi-gigabyte jump drives and DVD drives likely wouldn't

exist without rare earth magnets, which are often made from

a neodymium alloy but may also contain

praseodymium,

samarium,

gadolinium or

dysprosium.

Permanent

magnets are another big role for rare earths. Their light

weight and high magnetic strength have made it possible to

miniaturize a wide range of electronic parts, including many

used in home appliances, audio/video equipment, computers,

cars and military gear. Innovations like small,

multi-gigabyte jump drives and DVD drives likely wouldn't

exist without rare earth magnets, which are often made from

a neodymium alloy but may also contain

praseodymium,

samarium,

gadolinium or

dysprosium.

While producing rare earths can cause environmental

problems, they have an eco-friendly side, too. They're vital

to catalytic converters, hybrid cars and wind turbines, for

example, as well as energy-efficient fluorescent lamps and

magnetic-refrigeration systems. Their low toxicity is an

advantage, too, with lanthanum-nickel-hydride batteries

slowly replacing older kinds that use cadmium or lead. Red

pigments from

lanthanum or cerium are also phasing out dyes that

contain various toxins. (For more information, see the list

below of

rare earth metals and their uses.)

Lots of green technologies rely on rare earths, but

ironically, rare earth producers have a long history of

harming the environment to get the metals. Like many

industries that process mineral ores, they end up with toxic

byproducts known as "tailings," which can be contaminated

with radioactive uranium and thorium. In China, these

tailings are often dumped into "rare

earth lakes" like the ones pictured below:

Satellite view of

China's Baotou rare earths complex. Mines are at top right;

waste lakes are at left.

Ground-level view

of wastewater being pumped into a rare earth lake at Baotou.

As the AFP

reports, farmers near China's Baotou mine complain of

dying crops, lost teeth and lost hair, while soil and water

tests show high levels of carcinogens in the area. China has

only recently begun

cracking down on such pollution, perhaps learning a

lesson from Mountain Pass, Calif., which supplied most of

the world's rare earths until economic and environmental

pressures forced it to close in 2002. The mine's profits had

declined for years as China slashed rare earth prices with

its own mining frenzy, while a series of wastewater leaks

from 1984 to 1998 spilled thousands of gallons of toxic

sludge into the California desert, sullying the mine's

public image.

But as China's output now declines, rising prices have once

again opened the door for Mountain Pass. In April,

Molycorp Minerals hosted an event heralding the return

of its idle mine, which some politicians say is key to

reducing U.S. reliance on imports. "We must wean

ourselves off our total dependence on China for rare

earths," Rep. Mike Coffman, R-Colo., recently told the

Financial Times. It's hard to disagree, given rare earths'

global importance, but the specter of spills still lingers.

Molycorp knows that,

CEO Mark Smith told the Atlantic in 2009, and aims to be

"environmentally superior, not just compliant." The company

is spending $2.4 million a year on monitoring and

compliance, which raises costs, but Smith says that won't

deter anxious buyers. "We're being contacted by Fortune 100

companies who are worried about where they're going to get

their next pound of [rare earths]," he

told Bloomberg News in January. "What they want to talk

to us about is long-term, stable, secure supplies."

Molycorp

is allowed to deepen its pit at Mountain Pass (pictured) by

an extra 300 feet over the next 30 years, which could boost

global supplies of rare earths by 10 percent a year. And

it's not the only company itching to tap U.S. reserves:

Wings Enterprises is reviving its Pea Ridge mine in

Missouri, for instance, while a new mine in Wyoming may open

as early as 2014. Overall, experts say the growth of rare

earth mining is all but inevitable, adding a toxic asterisk

to many technologies designed to fight climate change.

Molycorp

is allowed to deepen its pit at Mountain Pass (pictured) by

an extra 300 feet over the next 30 years, which could boost

global supplies of rare earths by 10 percent a year. And

it's not the only company itching to tap U.S. reserves:

Wings Enterprises is reviving its Pea Ridge mine in

Missouri, for instance, while a new mine in Wyoming may open

as early as 2014. Overall, experts say the growth of rare

earth mining is all but inevitable, adding a toxic asterisk

to many technologies designed to fight climate change.

But there may be one way to reduce demand for new mining:

rare earth recycling. China's export policies have led

some Japanese companies to recycle rare earths, such as

Mitsubishi, which is studying the cost of reusing neodymium

and dysposium from washing machines and air conditioners.

Hitachi, which uses up to 600 tons of rare earths each year,

expects recycling to fill 10 percent of its needs by 2013.

The U.N. also

recently launched a project to track discarded "e-waste"

like cellphones and TVs, hoping to boost recycling not only

of rare earths but also gold, silver and copper. Yet until

such programs are more cost-effective, the U.S. and other

countries will almost certainly keep testing just how rare —

and how safe — rare earths really are.

See the list below to learn more about how each of the

17 rare earth minerals are used, or skip to the bottom of

the page for

links to more information.

Rare earths roster

-

Scandium: Added

to mercury vapor lamps to make their light look more like

sunlight. Also used in certain types of athletic equipment —

including aluminum baseball bats, bicycle frames and

lacrosse sticks — as well as fuel cells.

Scandium: Added

to mercury vapor lamps to make their light look more like

sunlight. Also used in certain types of athletic equipment —

including aluminum baseball bats, bicycle frames and

lacrosse sticks — as well as fuel cells. -

Yttrium: Produces

color in many TV picture tubes. Also conducts microwaves and

acoustic energy, simulates diamond gemstones, and

strengthens ceramics, glass, aluminum alloys and magnesium

alloys, among other uses.

Yttrium: Produces

color in many TV picture tubes. Also conducts microwaves and

acoustic energy, simulates diamond gemstones, and

strengthens ceramics, glass, aluminum alloys and magnesium

alloys, among other uses. -

Lanthanum:

One of several rare earths used to make carbon arc

lamps, which the film and TV industry use for studio and

projector lights. Also found in batteries, cigarette-lighter

flints and specialized types of glass, like camera lenses.

Lanthanum:

One of several rare earths used to make carbon arc

lamps, which the film and TV industry use for studio and

projector lights. Also found in batteries, cigarette-lighter

flints and specialized types of glass, like camera lenses. -

Cerium:

The most widespread of all rare earth metals. Used in

catalytic converters and diesel fuels to reduce vehicles'

carbon monoxide emissions. Also used in carbon arc lights,

lighter flints, glass polishers and self-cleaning ovens.

Cerium:

The most widespread of all rare earth metals. Used in

catalytic converters and diesel fuels to reduce vehicles'

carbon monoxide emissions. Also used in carbon arc lights,

lighter flints, glass polishers and self-cleaning ovens. -

Praseodymium:

Primarily used as an alloying agent with magnesium to

make high-strength metals for aircraft engines. Also may be

used as a signal amplifier in fiber-optic cables, and to

create the hard glass of welder's goggles.

Praseodymium:

Primarily used as an alloying agent with magnesium to

make high-strength metals for aircraft engines. Also may be

used as a signal amplifier in fiber-optic cables, and to

create the hard glass of welder's goggles. -

Neodymium:

Mainly used to make powerful neodymium magnets for

computer hard disks, wind turbines, hybrid cars, earbud

headphones and microphones. Also used to color glass and to

make lighter flints and welder's goggles.

Neodymium:

Mainly used to make powerful neodymium magnets for

computer hard disks, wind turbines, hybrid cars, earbud

headphones and microphones. Also used to color glass and to

make lighter flints and welder's goggles. -

Promethium:

Does not occur naturally on Earth; must be artificially

produced via uranium fission. Added to some kinds of

luminous paint and nuclear-powered microbatteries, with

potential use in portable X-ray devices.

Promethium:

Does not occur naturally on Earth; must be artificially

produced via uranium fission. Added to some kinds of

luminous paint and nuclear-powered microbatteries, with

potential use in portable X-ray devices. -

Samarium:

Mixed with cobalt to create a permanent magnet with the

highest demagnetization resistance of any known material.

Crucial for building "smart" missiles; also used in carbon

arc lamps, lighter flints and some types of glass.

Samarium:

Mixed with cobalt to create a permanent magnet with the

highest demagnetization resistance of any known material.

Crucial for building "smart" missiles; also used in carbon

arc lamps, lighter flints and some types of glass. -

Europium:

The most reactive of all rare earth metals. Used for

decades as a red phosphor in TV sets — and more recently in

computer monitors, fluorescent lamps and some types of

lasers — but otherwise has few commercial applications.

Europium:

The most reactive of all rare earth metals. Used for

decades as a red phosphor in TV sets — and more recently in

computer monitors, fluorescent lamps and some types of

lasers — but otherwise has few commercial applications. -

Gadolinium: Used

in some control rods at nuclear power plants. Also used in

medical applications such as magnetic resonance imaging

(MRI), and industrially to improve the workability of iron,

chromium and various other metals.

Gadolinium: Used

in some control rods at nuclear power plants. Also used in

medical applications such as magnetic resonance imaging

(MRI), and industrially to improve the workability of iron,

chromium and various other metals. -

Terbium:

Used in some solid-state technology, from advanced sonar

systems to small electronic sensors, as well as fuel cells

designed to operate at high temperatures. Also produces

laser light and green phosphors in TV tubes.

Terbium:

Used in some solid-state technology, from advanced sonar

systems to small electronic sensors, as well as fuel cells

designed to operate at high temperatures. Also produces

laser light and green phosphors in TV tubes. -

Dysprosium:

Used in some control rods at nuclear power plants. Also

used in certain kinds of lasers, high-intensity lighting,

and to raise the coercivity of high-powered permanent

magnets, such as those found in hybrid vehicles.

Dysprosium:

Used in some control rods at nuclear power plants. Also

used in certain kinds of lasers, high-intensity lighting,

and to raise the coercivity of high-powered permanent

magnets, such as those found in hybrid vehicles. -

Holmium:

Has the highest magnetic strength of any known element,

making it useful in industrial magnets as well as some

nuclear control rods. Also used in solid-state lasers and to

help color cubic zirconia and certain types of glass.

Holmium:

Has the highest magnetic strength of any known element,

making it useful in industrial magnets as well as some

nuclear control rods. Also used in solid-state lasers and to

help color cubic zirconia and certain types of glass. -

Erbium:

Used as a photographic filter and as a signal amplifier (aka

"doping agent") in fiber-optic cables. Also used in some

nuclear control rods, metallic alloys, and to color

specialized glass and porcelain in sunglasses and cheap

jewelry.

Erbium:

Used as a photographic filter and as a signal amplifier (aka

"doping agent") in fiber-optic cables. Also used in some

nuclear control rods, metallic alloys, and to color

specialized glass and porcelain in sunglasses and cheap

jewelry. -

Thulium:

The rarest of all naturally occurring rare earth metals. Has

few commercial applications, although it is used in some

surgical lasers. After being exposed to radiation in nuclear

reactors, it's also used in portable X-ray technology.

Thulium:

The rarest of all naturally occurring rare earth metals. Has

few commercial applications, although it is used in some

surgical lasers. After being exposed to radiation in nuclear

reactors, it's also used in portable X-ray technology. -

Ytterbium:

Used in some portable X-ray devices, but otherwise has

limited commercial uses. Among its specialty applications,

it's used in certain types of lasers, stress gauges for

earthquakes, and as a doping agent in fiber-optic cables.

Ytterbium:

Used in some portable X-ray devices, but otherwise has

limited commercial uses. Among its specialty applications,

it's used in certain types of lasers, stress gauges for

earthquakes, and as a doping agent in fiber-optic cables. -

Lutetium: Mainly

restricted to specialty uses, such as calculating the age of

meteorites or performing positron emission tomography (PET)

scans. Has also been used as a catalyst for the process of

"cracking" petroleum products at oil refineries.

Lutetium: Mainly

restricted to specialty uses, such as calculating the age of

meteorites or performing positron emission tomography (PET)

scans. Has also been used as a catalyst for the process of

"cracking" petroleum products at oil refineries.

Copyright © 2013 MNN

Holdings, LLC. All Rights Reserved.

http://www.mnn.com/earth-matters/translating-uncle-sam/stories/what-are-rare-earth-metals

http://www.mnn.com/earth-matters/translating-uncle-sam/stories/what-are-rare-earth-metals