Source: U.S. Energy Information Administration, 2012 Electric Power Annual and December 2013 Electric Power Monthly

Operators of coal-fired power plants throughout the U.S. are creating strategies to meet the Environmental Protection Agency's (EPA) Mercury and Air Toxics Standards (MATS) by the April 2015 deadline.

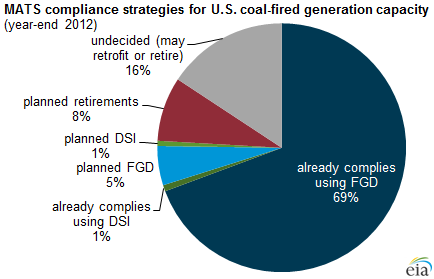

Sixteen percent of coal plant operators are still deciding which sites will upgrade or retire. The expenses associated with the necessary equipment to control emissions, such as flue gas desulfurization (FGD) and dry sorbent injection (DSI), play a major role in the decision process.

According to a report by the Energy Information Administration (EIA), at the end of 2012, 70 percent of coal-fired facilities had the necessary control equipment installed to meet the MATS. Six percent plan to add the equipment, while 8 percent of coal-fired power plant operators have announced plans to retire their facilities.

The MATS requires that operational coal-fired power plants incorporate maximum achievable control technologies (MACT) in order to control acid gases, toxic metals, and mercury emissions.

The standard incorporates a provision that permits state environmental agencies to allow one-year compliance exceptions, which many states are likely to utilize, the EIA said.

There are three main types of emissions that the MATS focuses on by including MACT compliance, which also overlap other emission regulations:

- Acid gas: A FGD or DSI framework will qualify as the MACT for acid gases. These systems also can omit sulfur dioxide (SO2) emissions. Although SO2 is not specifically addressed by the rule, it is regulated under Title IV of the Clean Air Act and the Clean Air Interstate Rule (CAIR). Sixty-nine percent of installed FGD systems regulate SO2 emissions.

- Toxic metals: FGD scrubbers with a fabric filter or an advanced electrostatic precipitator will likely qualify as the MACT for toxic metals. If a DSI system is utilized to control acid gases, a fabric filter must be incorporated to remove toxic metals. The accessible equipment is dictated by each plantís features.

- Mercury: The control supplies required to reduce mercury is determined by the type of coal burned and the plant configuration. In some cases an existing FGD scrubber and selective catalytic reduction system (SCR) can lower mercury emissions, where no additional controls are required. In other circumstances, activated carbon injection (ACI) frameworks may be needed to bring plants into compliance.

FGD scrubbers have higher capital expenses but lower operating costs than DSI frameworks, along with a higher removal rate for SO2 and other acid gases (90 percent of SO2 emissions for FGD, compared to 70 percent for DSI). DSI systems have significantly lower capital costs compared to FGDs, yet higher working expenses due to the high cost of the reagent required to remove emissions. This makes DSI systems more attractive for plants burning lower sulfur coal or for plants that operate infrequently. The low capital financing needed for DSI also makes it easier to recover costs. Installing a FGD scrubber would require the plant to operate more frequently to earn enough income to pay for the investment.

From 2005 to 2012, electric power producers omitted SO2 emissions by 67 percent.

Nitrogen oxide (NOx) emissions from the industry are expected to remain level through 2040 in the AEO2014 projection, since regulations on reducing NOx emissions have yet to be established.

The EIA predicts that SO2 emissions will decrease by 68 percent annually between 2015 and 2016. But they are anticipated to rise gradually, by 0.9 percent from 2016 to 2040. However, by 2040, levels are still expected to be 52 percent lower than 2012.

Since the MATS has more of an impact on SO2 emissions, NOx emissions stay moderately even through 2040. Annual NOx emissions from power production declined by 54 percent from 2005 to 2012, primarily due to the Clean Air Interstate Rule (CAIR).

Copyright © 2014: PennWell Corporation Subscribe to http://www.power-eng.com