Rice University's carbon capture breakthrough

Rice University scientists are announcing a carbon capture breakthrough that looks like a promising replacement for more costly, energy-intensive processes. The porous material created by the researchers sequesters carbon dioxide (CO2) at ambient temperature with pressure provided by the wellhead and lets it go once the pressure is released.

|

|

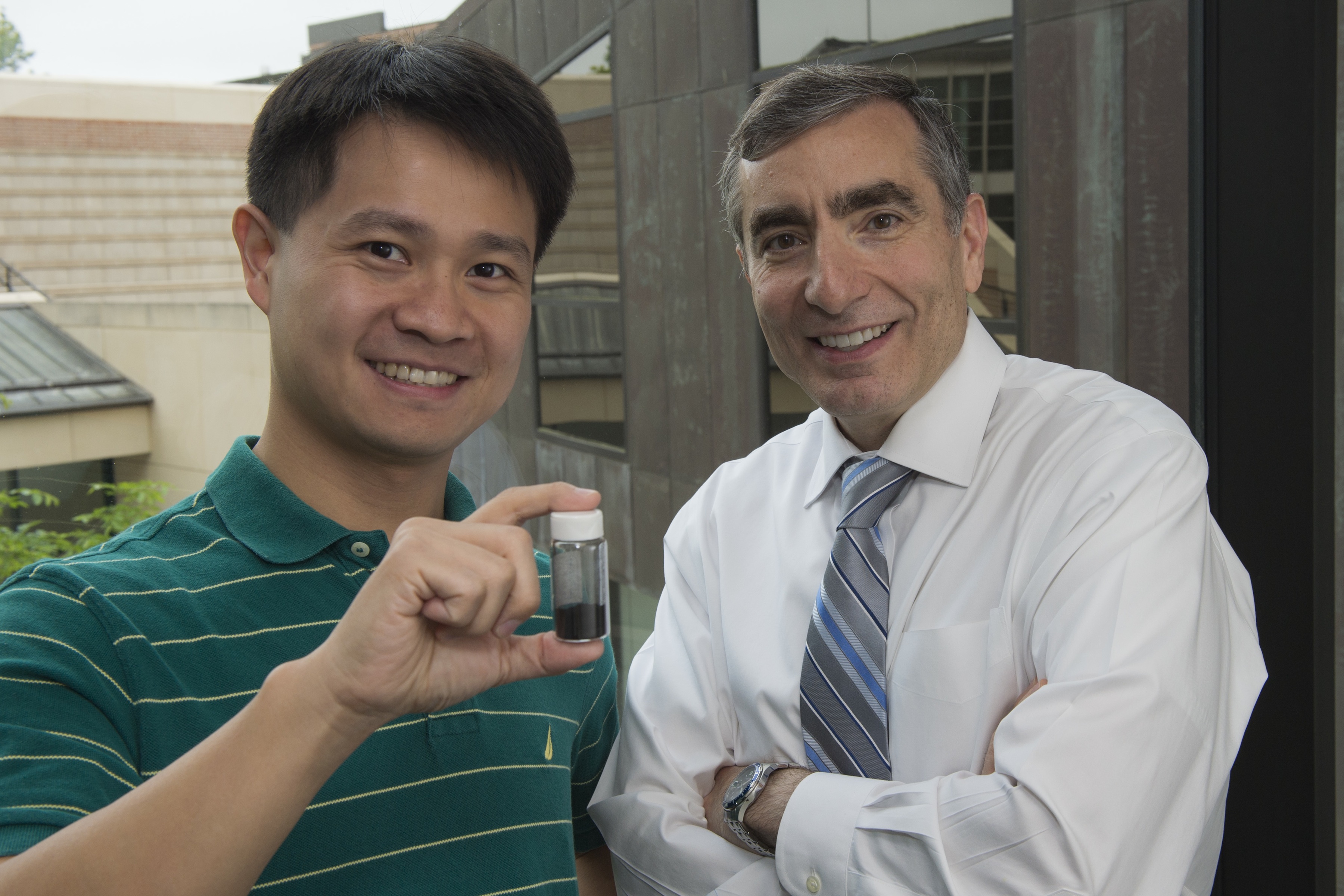

The vial of material has the ability to capture carbon from gas flowing out of a well and hold it until it can be put back underground or otherwise used. Credit: Jeff Fitlow/Rice University |

Natural gas is the cleanest fossil fuel, and development of cost-effective means to separate carbon dioxide during the production process will improve this advantage over other fossil fuels, and enable the economic production of gas resources with higher carbon dioxide content that would be too costly to recover using current carbon capture technologies. CO2 has traditionally been removed from natural gas to meet pipelines' specifications.

"Our technique allows one to specifically remove carbon dioxide at the source. It doesn't have to be transported to a collection station to do the separation. This will be especially effective offshore, where the footprint of traditional methods that involve scrubbing towers or membranes are too cumbersome," said Rice University researcher James Tour. "This will enable companies to pump carbon dioxide directly back downhole, where it's been for millions of years, or use it for enhanced oil recovery to further the release of oil and natural gas. Or they can package and sell it for other industrial applications."

The material, a nanoporous solid of carbon with nitrogen or sulfur, is inexpensive and simple to produce compared with the liquid amine-based scrubbers used now, which are corrosive and hard on equipment.

"They do capture carbon dioxide, but they need to be heated to about 140 degrees Celsius to release it for permanent storage," Tour said. "That's a terrible waste of energy."

The researchers treated their carbon source with potassium hydroxide at 600 degrees Celsius to produce the powders with either sulfur or nitrogen atoms evenly distributed through the resulting porous material. The sulfur-infused powder performed best, absorbing 82 percent of its weight in carbon dioxide. The nitrogen-infused powder was nearly as good and improved with further processing.

The material did not degrade over many cycles and is not expected to. More time and work on manufacturing and engineering aspects will be needed before the technology can be commercialized. However, that does not mean that executives should sit back and take a wait-and-see attitude toward greenhouse gas emissions reduction.

"If the oil and gas industry does not respond to concerns about carbon dioxide and other emissions, it could well face new regulations," said Tour, noting the new carbon pollution rules proposed earlier this week.

For more:

- see this

article

© 2014 FierceMarkets, a division of Questex Media Group LLC. All rights reserved.

http://www.fierceenergy.com/story/rice-universitys-carbon-capture-breakthrough/2014-06-05