Bring On The Bacteria: Conventional Treatment Methods Not Enough To Produce Safe Drinking Water

By Dr. Hans Peterson, Safe Drinking Water Foundation

Around the world there are guidelines and regulations regarding the quality of drinking water distributed by water treatment plants. These guidelines/regulations are sometimes national, such as U.S. regulations and Canadian guidelines. Others have adopted the same regulations covering many countries, such as European regulations. There are also the World Health Organization’s guidelines that all countries should try to follow.

These guidelines/regulations are mainly composed of upper limits for compounds/microbes that can be detrimental to humans. But, there are also lower limits, such as for free and total chlorine that are added to disinfect the water and to provide disinfection residuals in the distribution system. There are starting to be concerns about minimum limits, as different treatment technologies become prevalent. Water treated using Reverse Osmosis (RO), for example has a lack of calcium and magnesiu m in the water could be detrimental for humans. This is now resulting in recommendations for minimum levels of these compounds as well even if they are in a different category than the above. Maybe they should be included under “healthy water”.

This then begs the question—what is safe and healthy drinking water? Is it water that meets guidelines, regulations, and recommendations? But, even when an operator meets all of the regulations, guidelines and recommendations he/she can still face a host of different challenges that affect day-to-day operation of the water treatment plant. These challenges can consist of deposition of debris in the treated water reservoir and slime formation in the distribution system causing a loss of chlorine residuals in the distributed water.

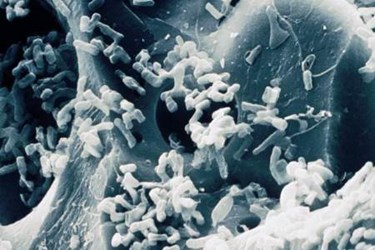

Bacterial slime growth in RO membranes, photo provided by Hans Peterson

What is missing? It is the lack of recognition by regulatory agencies around the world that any raw water source is a smorgasbord for bacteria. There are the compounds that are easy for bacteria to use like reduced gases, including hydrogen sulphide, methane etc., and then there are inorganic compounds, such as ammonium, manganese and arsenic. Bacteria can oxidize these compounds, moving them from a reduced state to an oxidized state while they gain energy in the process.

There are also organic compounds in the water that bacteria can use. These are called bioavailable organics and they are typically a small part of the total dissolved organics, but the constant supply of bioavailable organics carried by the raw water through the water treatment plant can create havoc even when the levels are small. Again, bacteria use these compounds and oxidize them to gain energy.

The above creates biological instability of even the best treated drinking water meeting all international guidelines/regulations. This biological instability is also the biggest cause for loss of chlorine residuals in the distribution system. Regrowth of coliforms in the distribution system is also stimulated by all the compounds that bacteria can use either as nutrient or energy sources.

This “smorgasbord ” problem cannot be solved with physics and chemistry. Biology is required. Coagulation and filtration has not got a chance and even tight RO membranes cannot entirely resolve biological instability. RO membranes are gas-permeable and direct RO treatment of groundwater sources often end up with unpleasant smells of the RO permeate. That is not surprising as anaerobic well waters often contain hydrogen sulphide (rotten egg smell) and other foul smelling gases as well as gases that don’t smell (methane for example). These gases have one thing in common—they are ice cream to bacteria. Another compound that is not removed properly by direct RO of groundwater is arsenic, as reduced arsenic (As3+) is not rejected well even by the tightest RO.

As long as we supply ice cream, steak, French fries and Greek salads to the bacteria we will continue to fail to produce safe drinking water even if we meet every regulation in the book. And, we will continue to make life for water treatment plant operators miserable as they do not have the right tools to fight this battle. It is a bit like trying to use a tea strainer to take out espresso ground coffee. It cannot be done.

What is the solution? We have a simple choice. We can either grow bacteria in the water treatment plant, or we will grow them in the treated water reservoirs and the distribution system. If membranes are used the bacteria will grow in the membranes whether the water is aerobic or anaerobic. The only difference is that anaerobic bacteria will grow under conditions of no oxygen while aerobic bacteria will grow if oxygen is present.

A regulator may think of bacteria as hetertrophic plate count, coliforms and E. coli. These bacteria are free-living in the water. This means that they are planktonic. If you want to treat drinking water using bacteria you need to look at a different category of bacteria; the biofilm forming bacteria. These bacteria grow on surfaces; they are not in the water. These are the bacteria we need to tease out from the source water and then grow them on a suitable filtration material. Biofilm forming bacteria respond to the environmental conditions in a filter and if they find those conditions they will secrete a strong “glue,” attaching them to the substrate from where they will carry out their water purification. This simply means that they will grow, taking up compounds that are either nutrient or energy sources for them.

Growing bacteria in a water treatment plant is actually really easy. Don’t pre-oxidize and you will grow bacteria even in sand filters. But, think about sand grains whether they are round or irregular, they only have the outside of the grains that are available for bacterial attachment. So, in terms of selecting a good material for biological treatment, sand will place close to the bottom of the heap. Of course, it is cheap. But, so is the biological treatment using it.

A much better way is to look for materials that are porous. In porous material, the surface area is much larger than in solid materials like sand. The quest really then becomes to define what are ideal conditions for bacterial growth? What is the best material for this growth? Once you define the ideal conditions and the best material you are on your way to converting your chemical/physical water treatment plant to a biological water treatment plant.

Soon you water treatment plant will produce treated water where the smorgasbord has either decreased drastically and, eventually, you will remove even the last bread crumbs. This spells biologically stable water, no loss of chlorine residuals in the distribution system, and five to ten year run times between cleanings of RO membranes.

Dr. Hans Peterson is a Safe Drinking Water Ambassador with the Safe Drinking Water Foundation, based in Canada. He was formerly the head of Saskatchewan Research Council’s Water Quality Team, president of WateResearch Corp., and executive director for the Safe Drinking Water Foundation. Peterson is working on the design of water treatment processes for exceedingly poor quality surface and groundwater in aboriginal communities in Canada. He can be reached at hans.peterson@yahoo.com

Copyright © 1996 - 2014, VertMarkets, Inc. All rights reserved. To subscribe or visit go to: http://www.wateronline.com