We've heard plenty on the wonderful properties of graphene, but the supermaterial par excellence still hasn't found its way to commercial products because it is too delicate for real-world conditions. Now, in a lucky and perhaps game-changing discovery, scientists at the Brookhaven National Laboratory (BNL) have found that placing graphene on top of common industrial-grade glass is a cheap and effective way of making it resilient and tunable, paving the way for the production of graphene-based electronics on a large scale.

One of the reasons for silicon's success in the semiconductor industry is that it is easily fine-tuned via a process known as "doping." This involves adding tiny concentrations (as low as a few parts per billion) of positively or negatively charged impurities that tweak silicon's electrical properties. Doping is a great tool to fit a semiconductor to a specific application, even though it is a delicate and costly process that adds to the material's complexity and can decrease its lifespan.

Graphene has excellent electrical, thermal and mechanical properties that would make it a vast improvement over silicon in many areas. However, doping graphene is proving a very difficult task, with the material (quite delicate to begin with, being only a single atom thick) degrading after just a few weeks of exposure to the environment.

Luckily, as BNL researchers Matthew Eisaman and colleagues were working on a graphene-based solar cell, they stumbled upon a cheap, effective and durable solution that may pave the way for mass-produced batteries, supercapacitors and solar panels which harness the still untapped power of graphene.

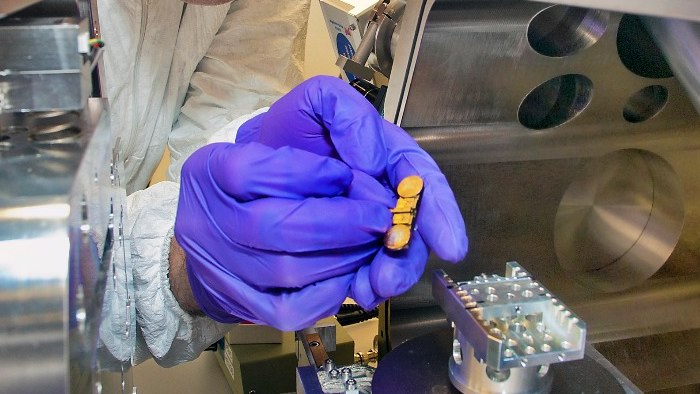

The scientists had built a solar cell by placing graphene on top of the high-performance semiconductor copper indium gallium diselenide (CIGS), which in turn was stacked on top of soda-lime glass (SLG), the same industrial-grade glass used for windows and bottles. When the researchers measured the baseline performance of the cell before proceeding to dope the graphene, they found to their surprise that the graphene had already been doped to the ideal level.

As they later discovered, this was because the sodium ions in the glass spontaneously transferred to the CIGS semiconductor by surface contact, and from there to the graphene, creating a concentration of impurities that happened to dope the graphene in just the right concentration.

Crucially, this method doesn't require high-temperature, chemical or vacuum processes, and the doping remained strong even when the cell was exposed to air for several weeks. What's more, the same method could also be applied to combinations of semiconductors and substrates other than CIGS and glass, where the concentration of doping impurities that reach graphene can be fine-tuned by inserting an insulating layer of the right thickness.

"We believe that this work could significantly advance the development of truly scalable graphene technologies," said Eisaman.

The next step for the researchers will be to demonstrate control over the doping concentrations and further study the durability of the treated graphene in real-world conditions.

Possible applications for graphene-based electronics include better solar cells, OLEDs, batteries and supercapacitors, as well as faster microchips that run on very little power.

The study is further expanded upon in an open-access paper appearing this week's edition of the journal Nature Scientific Reports.

Source: Brookhaven National Laboratory