How the internal combustion engine is being refined in 2017

The Infiniti VC-T engine is one of the latest engines providing improved fuel economy (Credit: Infiniti)

Although car manufacturers are embracing alternative power sources, they haven't given up on internal combustion just yet. Along with a push towards downsized turbo power, some of the smartest engineers in the world are using new techniques to make their engines more efficient and powerful. Here are a few of the most interesting modern takes on the internal combustion engine.

Along with hybrid and pure electric powertrains, Mazda says it will be offering the first compression ignition gasoline engine from 2019. At the moment, gasoline engines ignite the air-fuel mixture with a spark from the aptly-named spark plugs. Skyactiv-X engines will be capable of operating like a regular gasoline engine, but they will also be able to ignite the air-fuel mixture using compression.

This process probably sounds familiar – that's because it's how diesel engines operate. The process allows the engine to run at lower temperatures, helping to reduce the amount of energy usually lost to heat in gasoline engines. In turn, this allows Mazda to run with a leaner air-fuel mixture for better fuel consumption and lower emissions.

Mazda is, understandably, excited about the new setup, arguing it combines diesel fuel economy with gasoline throttle response. Other manufacturers have tried to nail the technology in concepts, but the fact compression ignition engines work best in a narrow temperature range has proven too great a hurdle to overcome. SkyActiv-X will avoid the issue by operating as a conventional, spark-ignition engine when conditions demand it.

Infiniti VC-T

Although they deliver impressive numbers on official test cycles, compact turbocharged engines come with an element of compromise. To make sure the air-fuel mixture doesn't prematurely detonate when the throttle is pinned and the turbocharger is singing, they need to have a low compression ratio. Under light loads, when the turbo isn't squeezing huge gobs of air into the cylinder, that lower compression ratio makes for a less efficient engine.

Infiniti can vary the compression ratio of the VC-T to facilitate punchy performance under heavy loads, with better fuel economy under light throttle openings. The ratio changes based on how hard the driver is pushing.

When you're just cruising along, the engine switches into the most efficient mode, with a peak compression ratio of 14:1. That's because the risk of pre-detonation, or knock, is low. But when you stamp on the throttle, the turbocharger starts forcing huge quantities of air into the cylinder, which in turn increases the risk of knock. That's why turbo tearaways like the Subaru WRX tend to run low compression ratios.

The VC-T engine is able to lower its compression ratio under heavy loads, reducing the risk of premature detonation without skimping on performance. The system works using an actuator arm, which manipulates the angle of a multi-link that sits around the camshaft. This, in turn, raises or lowers the bottom point of the piston stroke without actually moving the crankshaft or cylinder head. Sounds complicated, huh?

The results are simple, though. Infiniti says the technology will improve fuel economy by 27 percent, and the engine weighs just 22 lb (10 kg) more than the regular four-cylinder engines in the Infiniti lineup.

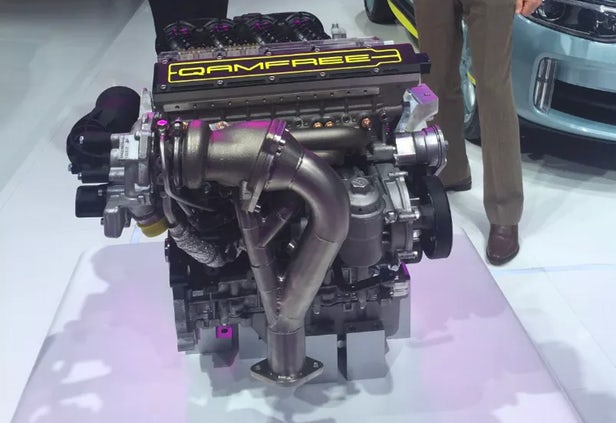

Qoros QamFree

Rather than using a traditional camshaft to control the valves, the QamFree uses a set of electro-hydraulic-pneumatic actuators to precisely control each valve in the engine.

In most engines, the rotating lobes of the camshaft push rockers, which in turn open the valves that are closed by valve springs. This process works, but it will always have a stage where the valves are partially open or partially closed, which means the system can't always operate at optimum efficiency.

Koenigsegg, one of the companies working with FreeValve to perfect the camshaft-free engine, likens this to playing a piano with both hands tied to the opposite ends of a broom stick. The electro-hydraulic-pneumatic actuators in the QamFree allow far greater control over the intake and exhaust valves in the engine, for a claimed improvement in fuel usage of between 12 and 17 percent.

The technology is also said to allow manufacturers to squeeze more power from a compact engine package, which should mean punchy performance from engines that still meet Euro and Chinese emissions standards.

In the case of the Qoros Q3 Concept pictured above, that means you get 230 hp (172 kW) and 320 Nm of torque from a 1.6-liter turbocharged engine. Compared to a conventional camshaft engine with similar specifications, the company says that's a 47 percent increase in power, a 45 percent power boost and a 15 percent reduction in fuel consumption.

Fiddling with the combustion cycle on all fronts

The latest Audi A4 is lighter and more aerodynamically efficient than its predecessor, but the fuel saving measures don't end there. It's offered with a 2.0-liter four-cylinder engine that makes use of a new combustion method that is designed to make it the most efficient gas engine in its class.

Audi says the combustion method in the new engine is similar to the Miller cycle, which leaves the intake valve open during part of the compression stroke and makes the engine compress against the pressure of the (mandatory) supercharger instead of the cylinder walls for greater (roughly 15 percent) efficiency.

Audi has shortened the intake time by reducing the crank

angle from 200 to 140 degrees, but the engine is still able to

achieve optimal cylinder charge thanks to higher boost pressure on

the inlet side. Under the new cycle, the intake valve closes earlier

than it otherwise would, which opens the door for an

efficiency-boosting high compression ratio.

As a result, the turbocharged four-cylinder makes 140 kW (190 hp) of power and 320 Nm (236 lb-ft) of torque, but still returns a miserly 5.0 L/100km (47 mpg) on the New European Drive Cycle.

Over at Toyota, the new Yaris is able to swap between the Atkinson and Otto cycles depending on how hard the driver is pushing. When the driver is cruising around, the engine's electric control system defaults to the Atkinson Cycle, keeping the intake valve open until the piston has completed between 20 and 30 percent of its upward journey on the compression stroke. This process sacrifices power density in favour of overall efficiency.

When the driver asks for more go, the system switches back to the Otto Cycle – the combustion cycle used in most spark-ignition engines. The engine has a sky-high 13.5:1 compression ratio, and a cooled exhaust-gas recirculation system helps bring combustion temperatures down – important for making sure you don't suffer knock with such a high compression ratio.

The changes have freed up 19 kW (27 hp) of extra power and 15 Nm (11 lb-ft) of torque in the fresh Yaris, all the while using around 12 percent less fuel then before.

And on a smaller scale...

Even seemingly average engines are filled with clever tech to save precious drops of fuel. Mercedes and Audi are using special coatings to cut friction within the cylinder liners, and even three-cylinder Ford engines now come with cylinder deactivation.

Of course, if you don't like the idea of internal combustion anymore, range on (and the range of) battery electric vehicles is on the improve, while hydrogen fuel cell vehicles are also showing promise.

http://newatlas.com/internal-combustion-engine-techniques/50929