Large quantities of synthetic spider silk spun on demand

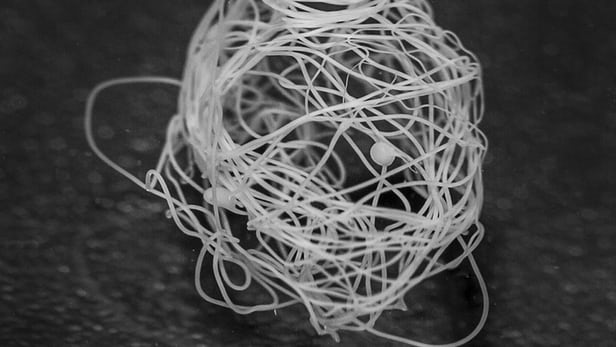

A new process developed by Swedish researchers using bacteria and spider silk proteins that mimics natural spinning production has provided the means to produce kilometer-long lengths of artificial web material(Credit: Lena Holm, Swedish University of Agricultural Sciences/Nature Chemical Biology)

Spiders may be scary for some people, but the silk that they produce to weave their webs is very appealing to many scientists. Amazingly tough, yet lightweight, spider silk has been used in everything from biodegradable sutures to violin strings, and even has possible applications in electronics and gene therapy. Unfortunately, spiders individually produce only small amounts of silk and wrangling enough of them into spooling out commercial quantities is nigh on impossible. Now a new prototype process that mimics the natural spinning process has been created, using bacteria and spider silk proteins to create large quantities of artificial web threads on demand.

Normally stockpiled as a watery solution in the silk glands of a spider, silk is made up of a number of proteins that solidify when spun into a fiber outside the body of the arachnid. The pH gradient found in these silk glands also affects individual segments of the proteins they contain to ensure that the fiber is formed quickly and consistently in exactly the right place.

Researchers Anna Rising, Jan Johansson, and Marlene Andersson working at the Swedish University of Agricultural Sciences (SLU) and at Karolinska Institutet took advantage of this knowledge to help create an artificial spider silk protein in bacteria that can then be bred en masse to produce industrial quantities of web material.

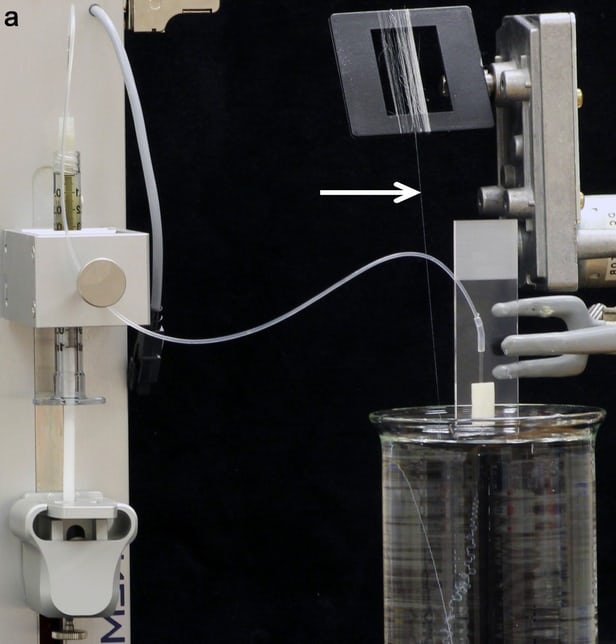

After the artificial protein is exuded from

the bacteria, the researchers use a simple biomimetic

process (that is, one that mimics nature) to ape a

spider silk gland spinning apparatus by using a syringe

to pump it through a glass capillary extruder to produce

kilometer-long fibers controlled by the manipulation of

pH levels. Fibers for the artificial silk produced using

this new method are around 40 micrometers in diameter.

"This is the first successful example of biomimetic spider silk spinning," said Anna Rising. "We have designed a process that recapitulates many of the complex molecular mechanisms of native silk spinning. In the future this may allow industrial production of artificial spider silk for biomaterial applications or for the manufacture of advanced textiles."

The results of this research were recently

published in the Nature journal

Chemical Biology

The short video below shows the silk being produced in the laboratory.

Source: SLU